Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Revolutionizing Kitchenware Manufacturing: Exploring Metal Laser Cutting Machine Factories

In the fast-paced world of kitchenware manufacturing, precision and efficiency are paramount. As demand for high-quality kitchenware continues to rise, manufacturers are turning to advanced technologies to streamline their production processes. One such technology that has revolutionized the industry is metal laser cutting machines. In this blog post, we'll delve into the world of kitchenware metal laser cutting machine factories and explore how these cutting-edge facilities are shaping the future of kitchenware production.

Chapter 1: The Rise of Metal Laser Cutting Machines

Evolution of Kitchenware Manufacturing: Traditionally, kitchenware manufacturing involved labor-intensive processes such as stamping, punching, and cutting. However, with the advent of metal laser cutting technology, the landscape has undergone a significant transformation. Metal laser cutting machines utilize high-powered lasers to precisely cut, engrave, and shape metal sheets with unparalleled accuracy and speed.

Introduction to Metal Laser Cutting Technology: Metal laser cutting machines work by directing a focused beam of laser light onto the surface of the material, melting, burning, or vaporizing it to create intricate shapes and designs. This technology offers several advantages over traditional cutting methods, including higher precision, faster production speeds, and the ability to work with a wide range of materials, including stainless steel, aluminum, and copper.

Advantages of Metal Laser Cutting Machines in Kitchenware Production: In the context of kitchenware manufacturing, metal laser cutting machines offer numerous benefits. Firstly, they enable manufacturers to produce complex shapes and designs with utmost precision, resulting in finished products that meet strict quality standards. Additionally, laser cutting machines are highly versatile and can accommodate various thicknesses and types of metal, allowing for greater design flexibility and customization options. Moreover, these machines operate with exceptional speed and efficiency, minimizing production time and maximizing productivity. Overall, metal laser cutting technology has revolutionized the way kitchenware is manufactured, paving the way for higher quality products and more efficient production processes.

Chapter 2: Exploring Kitchenware Metal Laser Cutting Machine Factories

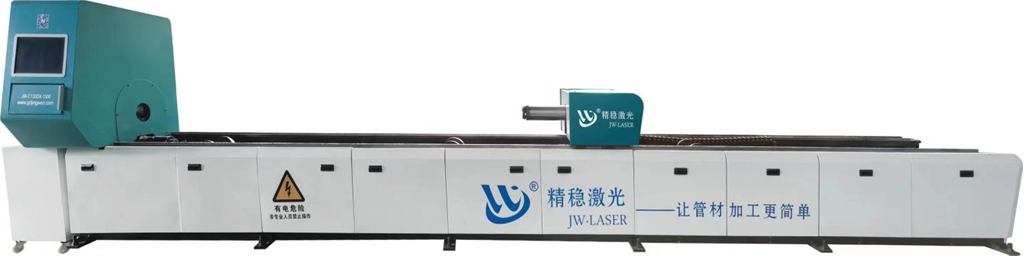

Overview of Modern Kitchenware Metal Laser Cutting Machine Factories: Today's kitchenware metal laser cutting machine factories are equipped with state-of-the-art facilities and cutting-edge technology to meet the demands of modern manufacturing. These factories typically feature a range of laser cutting machines, including CO2 lasers and fiber lasers, capable of handling various metal types and thicknesses. Additionally, they employ skilled technicians and engineers who oversee the production process and ensure quality control at every stage.

State-of-the-Art Equipment and Machinery: The factories invest heavily in advanced equipment and machinery to maintain a competitive edge in the market. This includes laser cutting machines with high wattage capabilities, precision optics, and automated systems for efficient material handling and processing. By leveraging the latest technology, these factories can achieve superior cutting accuracy and consistency while optimizing production efficiency.

Skilled Workforce and Expertise: A key component of successful kitchenware metal laser cutting machine factories is their skilled workforce. These facilities employ experienced technicians, engineers, and operators who possess in-depth knowledge of laser cutting technology and metal fabrication techniques. With their expertise, they can program and operate the laser cutting machines to achieve the desired results, ensuring that each product meets the highest standards of quality and craftsmanship.

Quality Control Measures and Standards: Quality control is paramount in kitchenware manufacturing, and metal laser cutting machine factories implement rigorous quality control measures to maintain product excellence. This includes comprehensive inspection processes, material testing, and adherence to industry standards and regulations. By prioritizing quality at every step of the production process, these factories uphold their reputation for delivering superior kitchenware products to consumers.

Chapter 3: Applications of Metal Laser Cutting Machines in Kitchenware Manufacturing

Cutting and Shaping Stainless Steel Cookware: One of the primary applications of metal laser cutting machines in kitchenware manufacturing is the cutting and shaping of stainless steel cookware. Laser cutting technology allows manufacturers to create precise shapes and intricate designs on stainless steel sheets, resulting in high-quality cookware products with seamless edges and flawless finishes.

Precision Cutting of Kitchen Utensils and Tools: Metal laser cutting machines are also used to fabricate kitchen utensils and tools with exceptional precision and accuracy. Whether it's cutting out knife blades, shaping measuring spoons, or engraving patterns on spatulas, laser cutting technology enables manufacturers to produce kitchenware items with intricate details and consistent quality.

Engraving and Marking on Metal Surfaces: Another valuable application of metal laser cutting machines is engraving and marking on metal surfaces. This capability allows manufacturers to add logos, branding, or decorative patterns to their kitchenware products, enhancing their aesthetic appeal and brand recognition.

Customization and Personalization Options: Metal laser cutting machines offer unparalleled customization and personalization options for kitchenware products. Whether it's creating custom designs, adding personalized messages, or incorporating unique features, laser cutting technology empowers manufacturers to cater to the individual preferences and needs of their customers, thereby enhancing customer satisfaction and brand loyalty.

Chapter 4: Advantages of Choosing Kitchenware Metal Laser Cutting Machine Factories

Superior Quality and Precision: When opting for kitchenware metal laser cutting machine factories, manufacturers can expect superior quality and precision in their products. Laser cutting technology enables precise cutting, shaping, and engraving of metal sheets, resulting in finished products with seamless edges, intricate designs, and consistent quality.

Efficiency and Productivity: Metal laser cutting machines offer unparalleled efficiency and productivity in kitchenware manufacturing. These machines operate at high speeds and can handle large volumes of work with minimal downtime, ensuring fast turnaround times and increased production capacity.

Cost-Effectiveness: Despite the initial investment in metal laser cutting machines, choosing a kitchenware metal laser cutting machine factory can be cost-effective in the long run. The efficiency and productivity of these machines translate into lower production costs per unit, enabling manufacturers to remain competitive in the market while maintaining profit margins.

Flexibility and Versatility: Kitchenware metal laser cutting machine factories offer flexibility and versatility in product design and customization. Whether it's creating unique shapes, intricate patterns, or personalized engravings, laser cutting technology allows for endless possibilities, enabling manufacturers to cater to diverse customer preferences and market demands.

Streamlined Production Process: By partnering with kitchenware metal laser cutting machine factories, manufacturers can streamline their production process and optimize workflow efficiency. These factories typically employ advanced automation and computerized systems for material handling, processing, and quality control, resulting in a seamless and efficient production process from start to finish.

Chapter 5: Case Studies: Success Stories from Satisfied Customers

Case Study 1: XYZ Kitchenware Company: XYZ Kitchenware Company, a leading manufacturer of high-end kitchenware products, partnered with a reputable metal laser cutting machine factory to enhance its production capabilities. By leveraging state-of-the-art laser cutting technology, the company was able to achieve greater precision, efficiency, and customization options in its product offerings. As a result, XYZ Kitchenware Company experienced increased customer satisfaction, expanded market share, and improved profitability.

Case Study 2: ABC Cookware Co.: ABC Cookware Co., a startup specializing in premium cookware products, collaborated with a renowned kitchenware metal laser cutting machine factory to bring its innovative designs to life. With the factory's expertise in laser cutting technology, ABC Cookware Co. was able to create sleek and sophisticated cookware pieces with intricate details and flawless finishes. The partnership propelled ABC Cookware Co. to success, earning accolades from customers and industry experts alike.

Chapter 6: Conclusion

In conclusion, kitchenware metal laser cutting machine factories play a pivotal role in revolutionizing the kitchenware manufacturing industry. By harnessing the power of laser cutting technology, these factories offer superior quality, efficiency, and customization options for kitchenware products. Manufacturers stand to benefit from partnering with reputable metal laser cutting machine factories, as it enables them to stay ahead of the competition, meet evolving customer demands, and achieve business success in the competitive kitchenware market.