Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

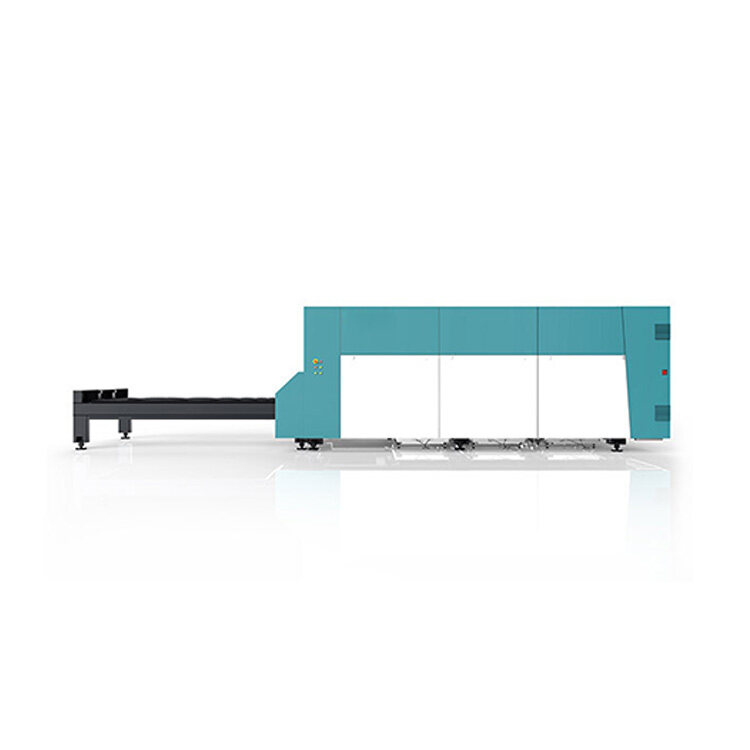

Metal Pipe Laser Cutting Machine

(15)C250D aluminum round pipe laser cutting machine

Several application scenarios for the round pipe laser cutting machine result in a diversity of tube shapes, which raises the bar for the metal tube cutting process. When compared to conventional cutting, laser cutting is flexible, doesn't require opening molds, saves a lot of time developing new products, is quick and precise, and can be used to cut holes in pipes as well as cut lines and use conventional ways. precise cutting of numerous difficult-to-achieve special-shaped and intricate artwork.

C250D stainless steel round pipe laser cutting machine

A specialized machine tool known as a round tube laser cutting machine employs laser technology to carve different graphics on pipe fittings and profiles. It is a high-tech product that combines laser cutting, numerical control technology, and precise equipment. It is the equipment of choice for the non-contact metal pipe processing business due to its professionalism, high speed, high precision, high efficiency, and high cost performance. It won't apply any pressure to the pipe wall at any point during the processing, thus the pipe's outer surface won't deform or collapse.

C200D aluminum round pipe laser cutting machine

Several industries employ the round tube laser cutting machine, which significantly decreases processing time, lowers processing costs, and raises the caliber of the finished product. Handicrafts, electronics, toys, sheet metal, hardware, jewelry, nameplates, ads, packaging, steel constructions, precision machinery, car parts, glass, and other sectors are among those involved. Stainless steel plates, iron plates, aluminum materials, ceramic sheets, silicon sheets, diamonds, etc. are typical materials used for laser cutting.

C200D stainless steel round pipe laser cutting machine

Round tube laser cutting machine is a small automatic laser tube cutting machine especially suitable for cutting thin-walled round tubes! This small automatic laser tube cutting machine is specially designed for cutting thin-walled metal round tubes. It adopts laser cutting, which is fast, burr-free, and the cut is smooth, saving subsequent processes. It is suitable for mosquito net tubes, mop tubes, furniture tubes, etc.

Multifunctional laser metal pipe cutting machine

(17)C120X aluminum pipe high precision laser cutting machine

For cutting unique profiles, a high-precision laser pipe cutting machine is appropriate. Moreover, it has an autonomous material-pushing system to cut down on cutting expenses and produce "zero tailings." It is widely employed in a variety of industries, including sports equipment, chemical equipment, and pipelines for oil. can cut aluminum, stainless steel, and carbon steel.

C120X stainless steel pipe high precision laser cutting machine

Metal is typically cut using high-precision laser cutting devices. When cutting metal materials with a diameter of 1mm, the laser cutting machine's diameter of the laser beam can reach about 0.2mm, and the cutting pattern is extremely accurate. This not only enhances the technical content and artistic taste of sheet metal processing, but also raises the profit margin. As a result, in order to improve the performance of the machinery, we must value and standardize the operation of high-precision laser cutting machines.

C120X carbon steel pipe high precision laser cutting machine

High-precision laser cutting machines have improved as a new type of cutting equipment in recent years. In terms of efficiency and stability, high-precision laser processing technology considerably outperforms conventional processing techniques and can add significant value to businesses.

C90X aluminum pipe high precision laser cutting machine

The high-precision laser cutting machine avoids material waste by automatic computer typesetting and nesting, realizes fair usage of metal sheets, develops endless concepts and styles in a restricted area, and cuts edges smoothly and neatly.

Metal Sheet Laser Cutting Machine

(1)DF-3015X Metal Sheet Laser Cutting Machine

Our DF-3015X Metal Sheet Laser Cutting Machine uses an imported servo motor that offers excellent performance, high speed, stability, and durability, ensuring the machine's overall high speed and acceleration.