Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Laser welding machines

(1)1500T laser welding machines

The laser welding machine is a new generation of non-contact welding equipment that uses lasers. Throughout the procedure, there is no requirement for pressurization. The high-energy laser beam is directly focused on the material's surface, and as a result of the interaction between the laser and the substance, the interior of the material melts, then cools and crystallizes to form the weld.

Automation Equipment

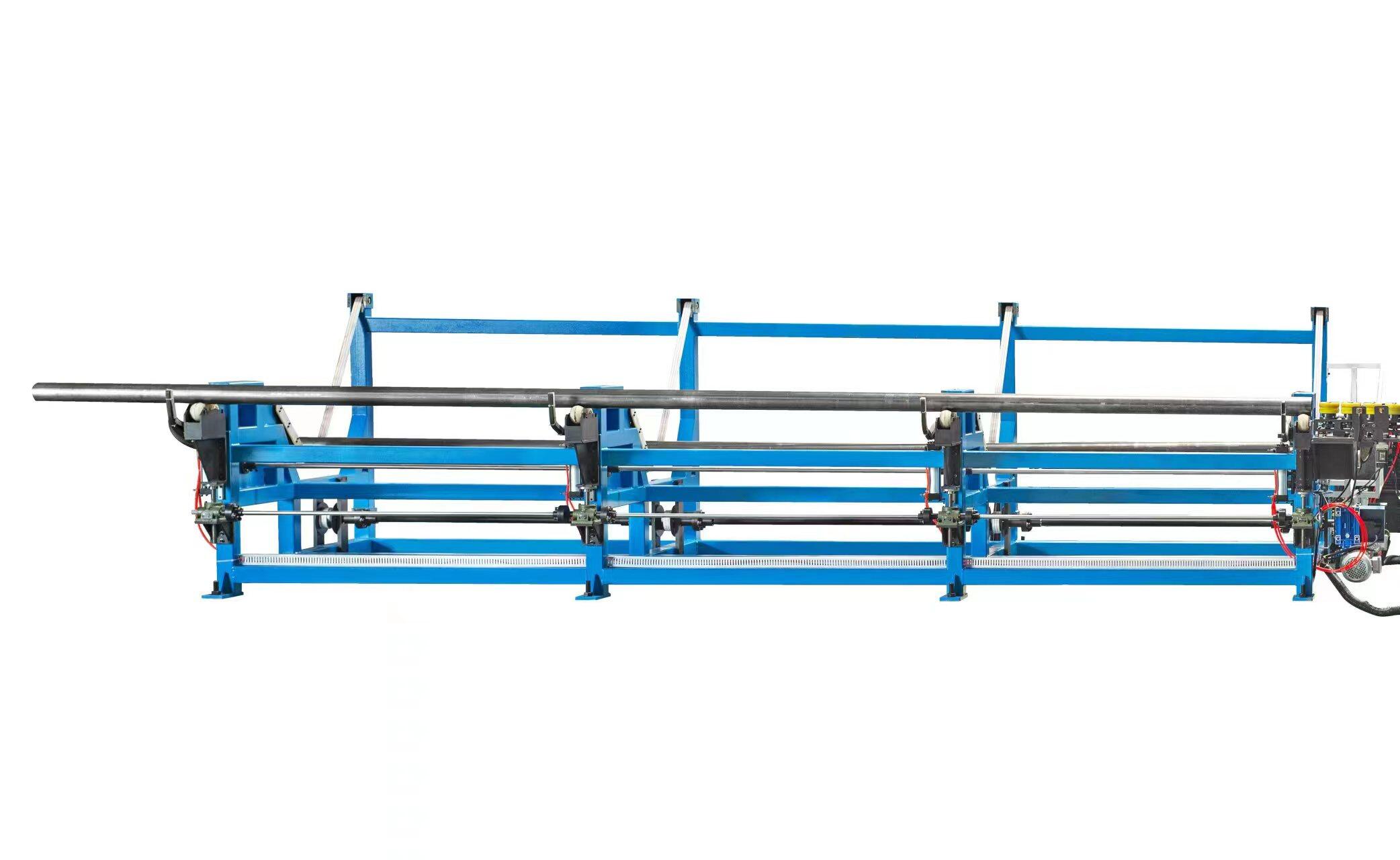

(2)Fully automatic loading rack

A newly created feeding rack for supporting the laser cutting machine is the fully automatic loading rack. It has high efficiency, consistent feeding, and complete automatic control.

Semi-automatic loading rack

The one-button semi-automatic loading rack is simple to use and can increase work productivity. However, when changing the kind of tube, you must manually adjust the size restriction of the tube loading. The equipment is light and has a small footprint, so it can be transported and docked with ease. The structure is straightforward, which can account for the stability of the equipment.

Machine Components

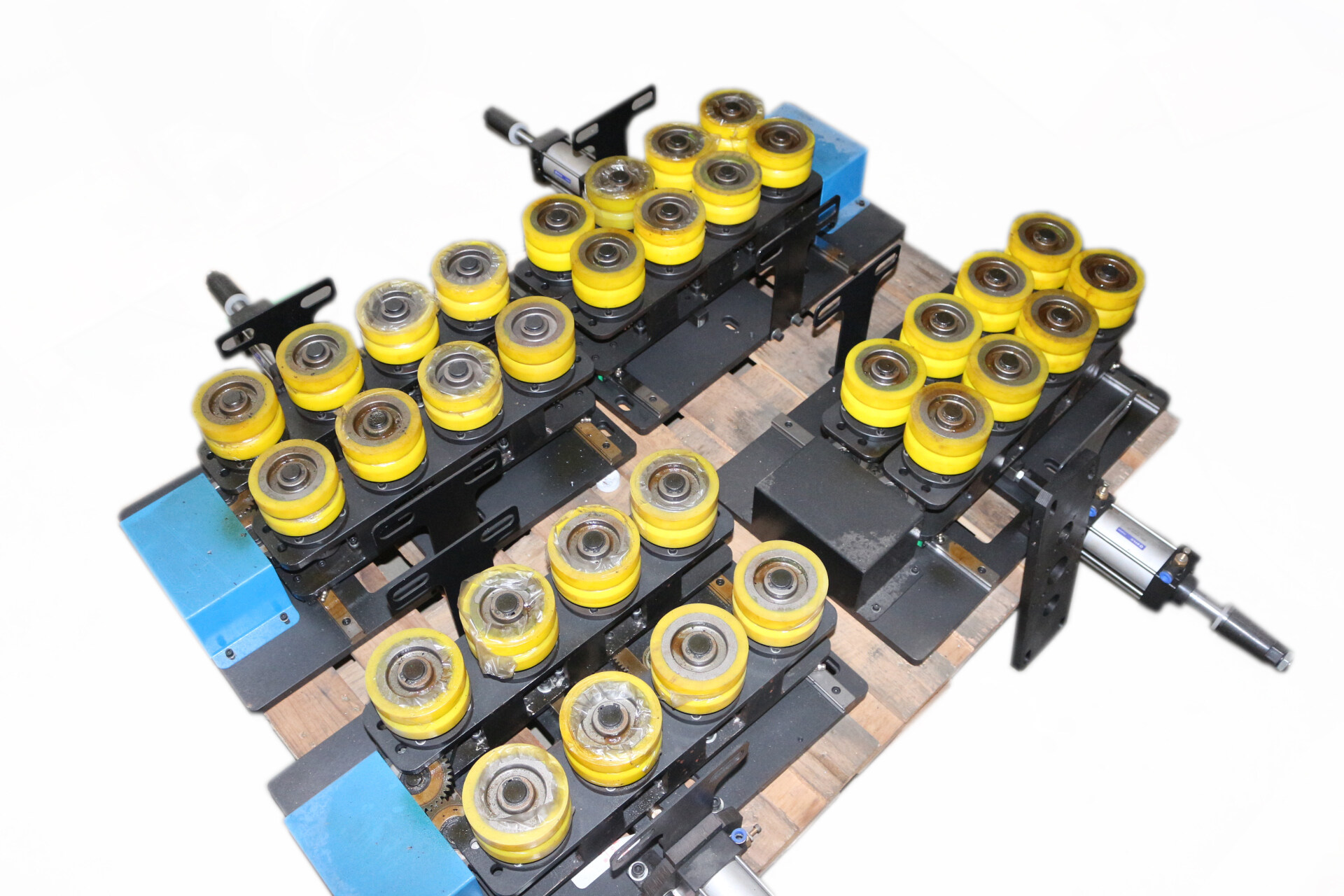

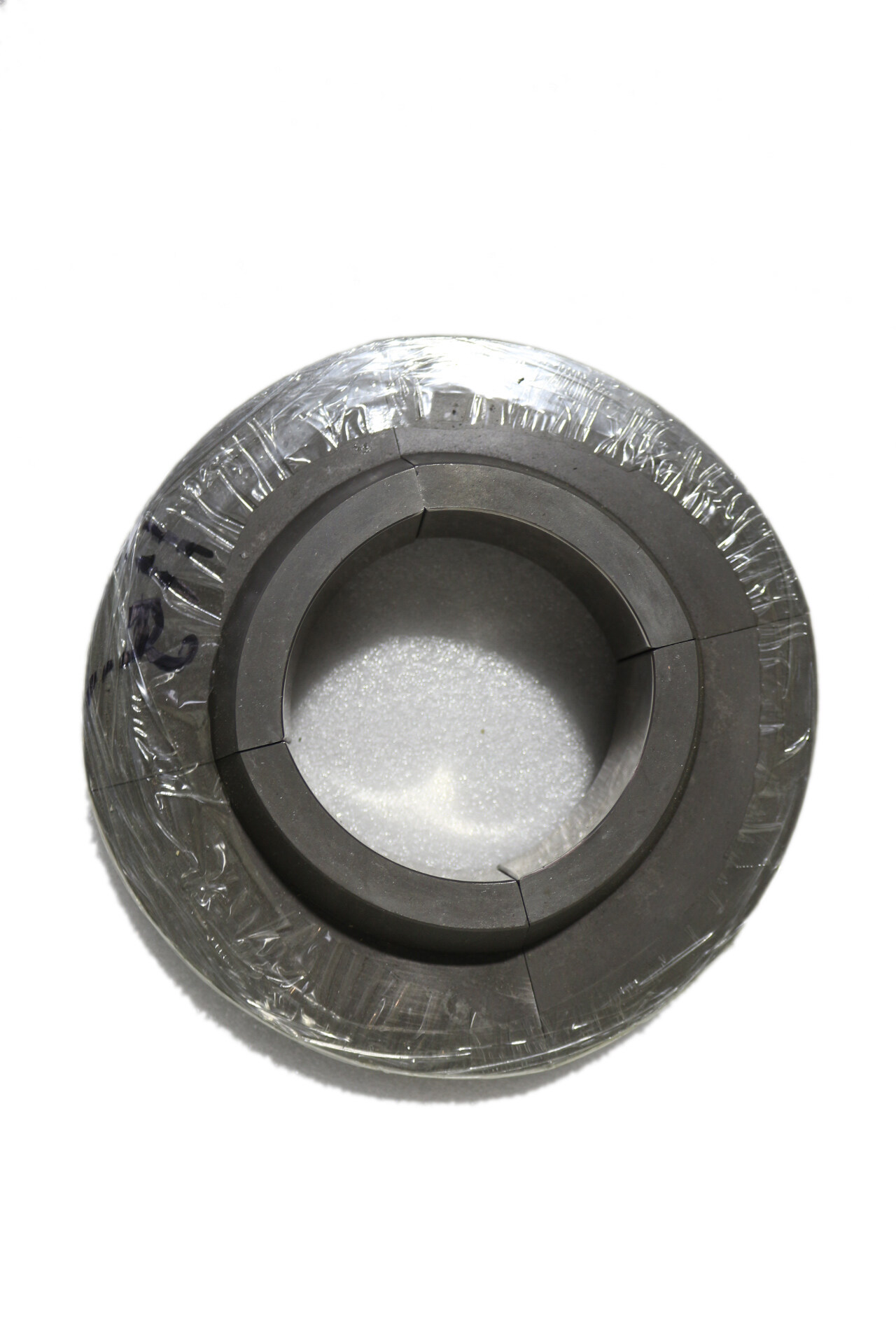

(12)Centering feeding wheel

Introducing the Centering Feeding Wheel, a revolutionary tool designed to enhance precision and efficiency in your manufacturing process. This innovative device ensures accurate alignment and smooth feeding of materials, eliminating errors and reducing downtime. Experience seamless operations and improved productivity with the Centering Feeding Wheel.

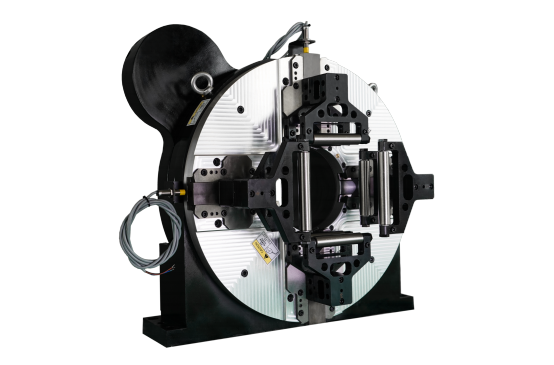

Hollow Pneumatic Rotary Chuck

A tapping chuck called a hollow pneumatic rotary chuck is used on machine machines to clamp taps while internally threaded holes are being processed. Tap chucks, chuck jackets, compression springs, steel balls, and tap jackets make up the majority of its parts.

Pneumatic Double Chuck

The uniformly spaced movable jaws on the chuck body of the laser pneumatic chuck move radially to clamp and position the workpiece. The moving jaw, the transmission mechanism for the moving jaw, and the chuck body normally make up the laser pneumatic chuck.

Pipe Welding Machine Tool

The major applications of pipe welding machine tools are the fabrication of carbon and stainless steel pipes for home furnishings, products, and appliances. Round pipes, square pipes, and rectangular pipes can be fashioned out following the molding of this group of elements. Also, it has the ability to create pipes that are elliptical, semicircular, plum blossom-shaped, and other unique shapes. such as electric heating pipes, burglar-proof doors and windows, and stainless steel stair railings.