Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

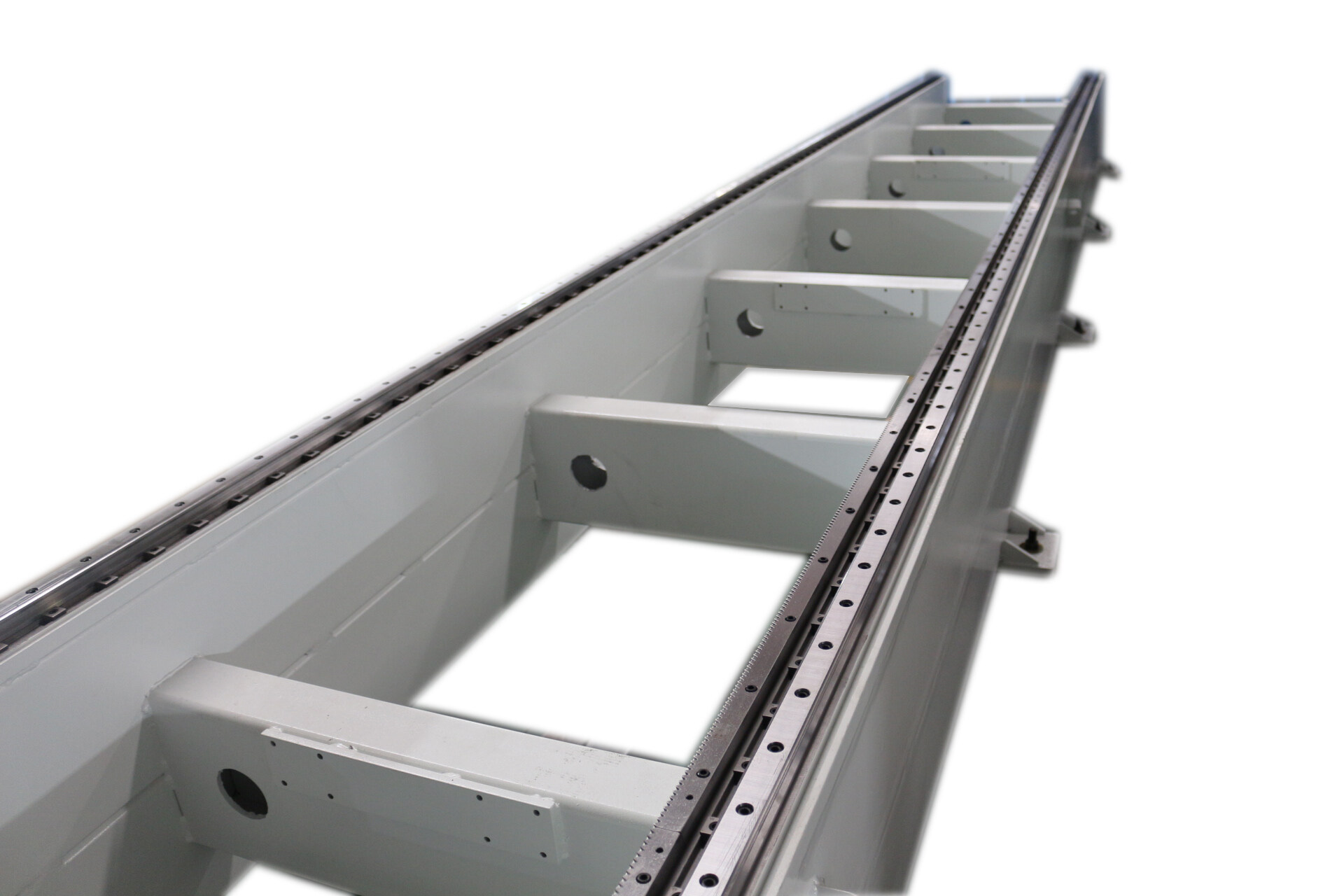

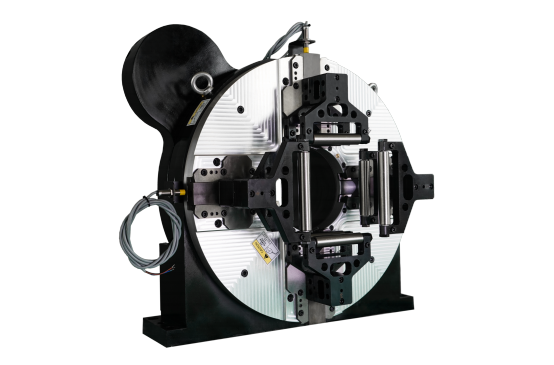

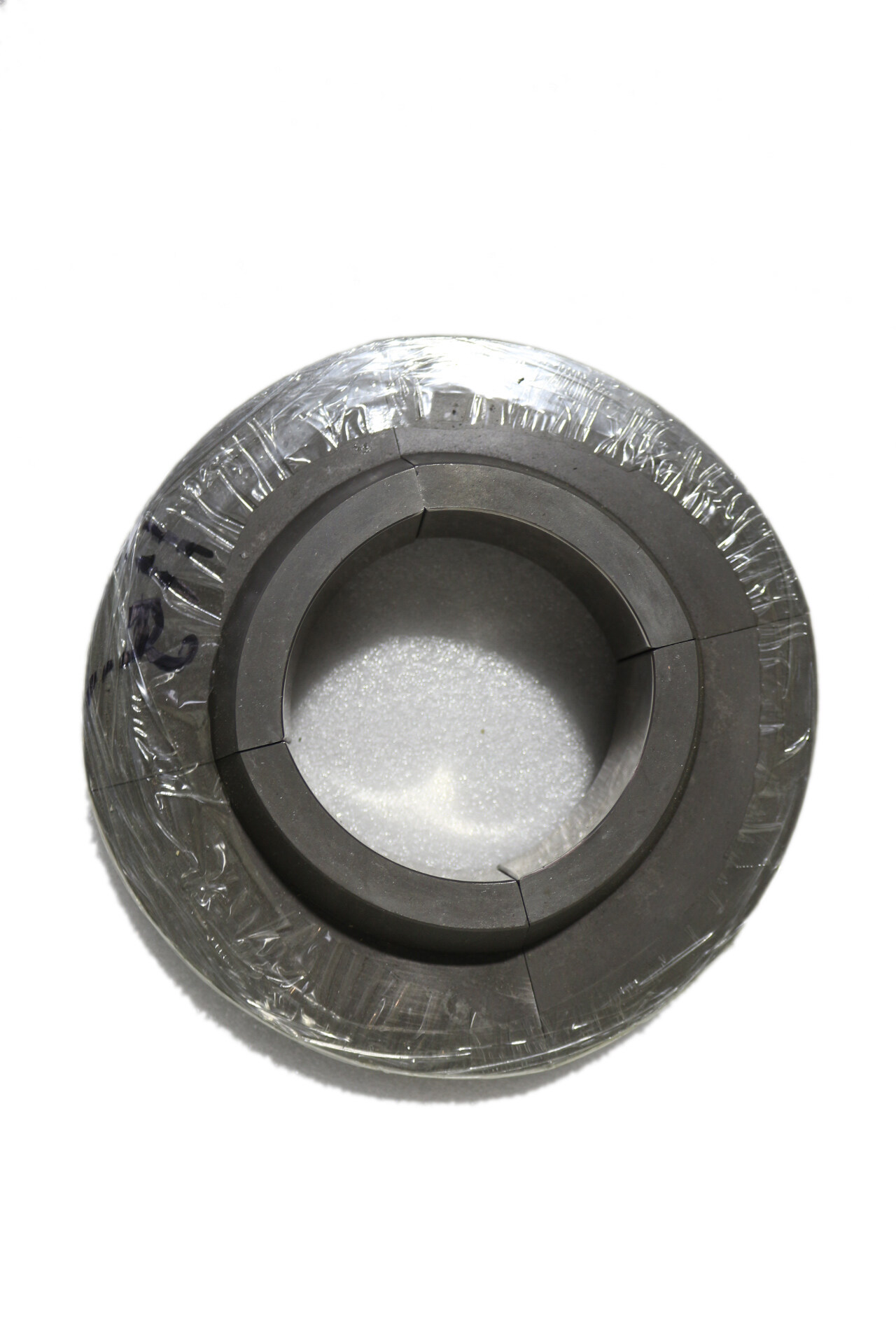

Pipe Welding Machine Tool

The major applications of pipe welding machine tools are the fabrication of carbon and stainless steel pipes for home furnishings, products, and appliances. Round pipes, square pipes, and rectangular pipes can be fashioned out following the molding of this group of elements. Also, it has the ability to create pipes that are elliptical, semicircular, plum blossom-shaped, and other unique shapes. such as electric heating pipes, burglar-proof doors and windows, and stainless steel stair railings.

Pipe Welding Machine Tool

Pipe Welding Machine Tool is mainly used for the production of stainless steel pipes and carbon steel pipes for decoration, products, and household appliances. After the molding of this series of units, round pipes, square pipes, and rectangular pipes can be drawn out. It can also produce elliptical pipes, semi-circular pipes, plum blossom pipes, and other special-shaped pipes. Such as stainless steel staircase handrails, burglar-proof doors, and windows, electric heating pipes, etc.

The automated production process of Pipe Welding Machine Tool

Through the continuous forming process of uncoiling, feeding guidance, marking, forming, welding, external weld grinding, shaping, sizing, sizing, cutting (coil), jointing, etc., the structure is fine and the operation is simple.

The features of Pipe Welding Machine Tool

The machine is strong, durable, high precision, fully automated, simple to operate, continuous production, high efficiency, less waste of materials, high yield, and low production cost.

The precautions of Pipe Welding Machine Tool

- Before starting, according to the lubrication requirements, injecting different lubricants into the parts where the lubricating oil is required to be injected.

- First, check whether the electrical switches are in the 0 positions, then turn on the power supply.

- Check whether the mechanical parts and pneumatic system are normal or not. If there are abnormal phenomena, they should be checked and eliminated in time so as not to cause mechanical equipment accidents.

- Let the motor run empty for 2-3 minutes before going to work every morning. The transmission gears are equal to 0. When driving, the operator is not allowed to leave the machine tool and do other irrelevant things.

- It is strictly prohibited to wear gloves to boot, long-sleeved clothes must wear hand sleeves, and long hair must wear a hat.

- Do not wipe the rotating parts when starting.

- Correctly adjust the mold, not vigorously under pressure, in place.

- During the operation, you are not allowed to leave the machine tool. You are not allowed to do other irrelevant things and pay attention to whether the welds are normal.

- If abnormal phenomena are found in operation, such as smoke, burning odor, sudden fuse burning, sudden extinguishment of indicator lights and timely switching off the power switch to be checked out, then turn on the operation after troubleshooting.