Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

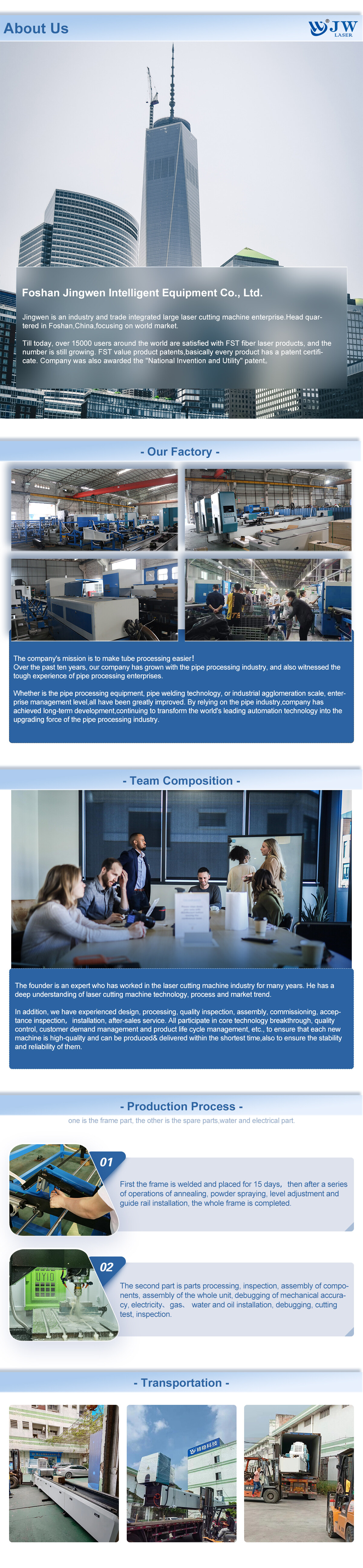

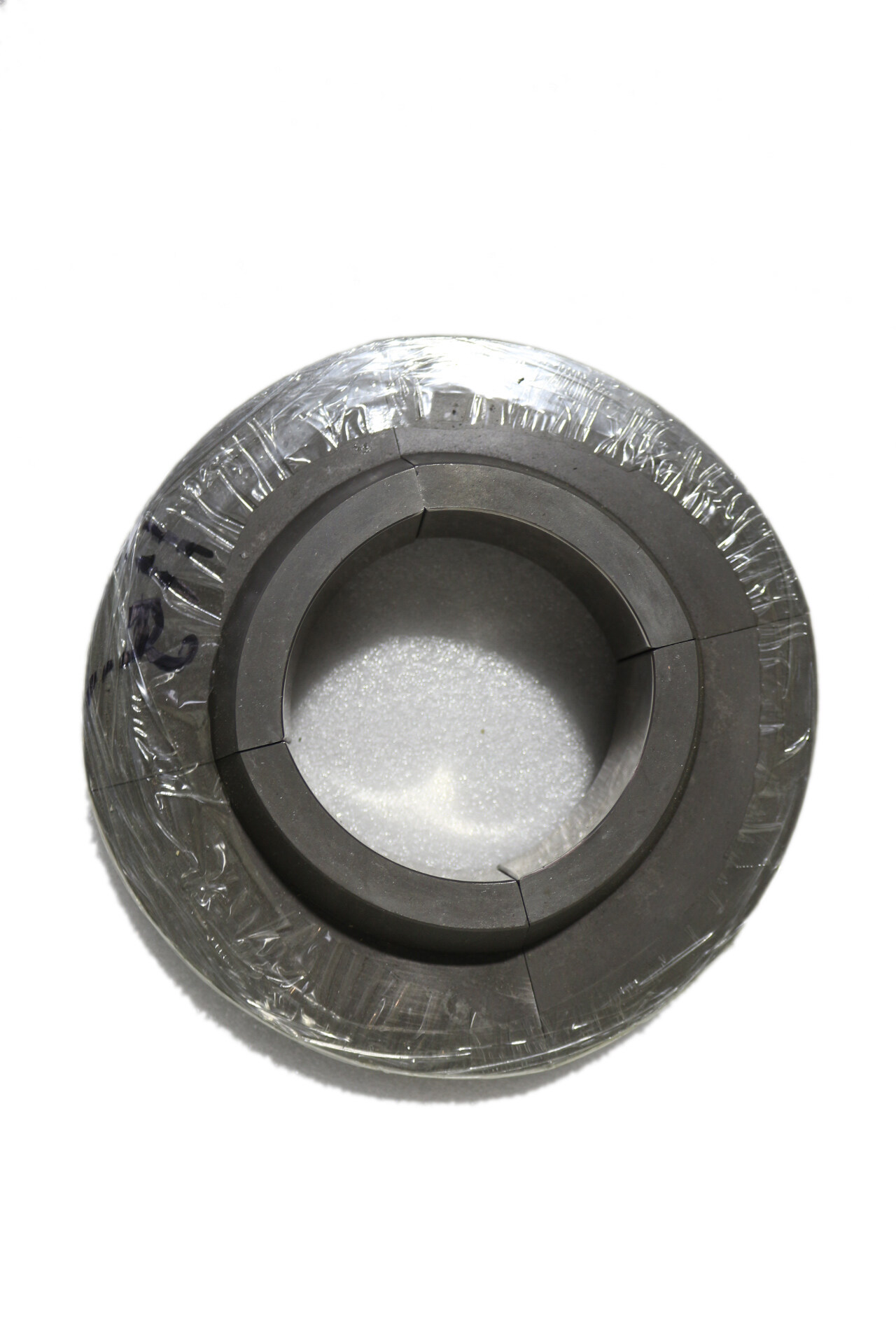

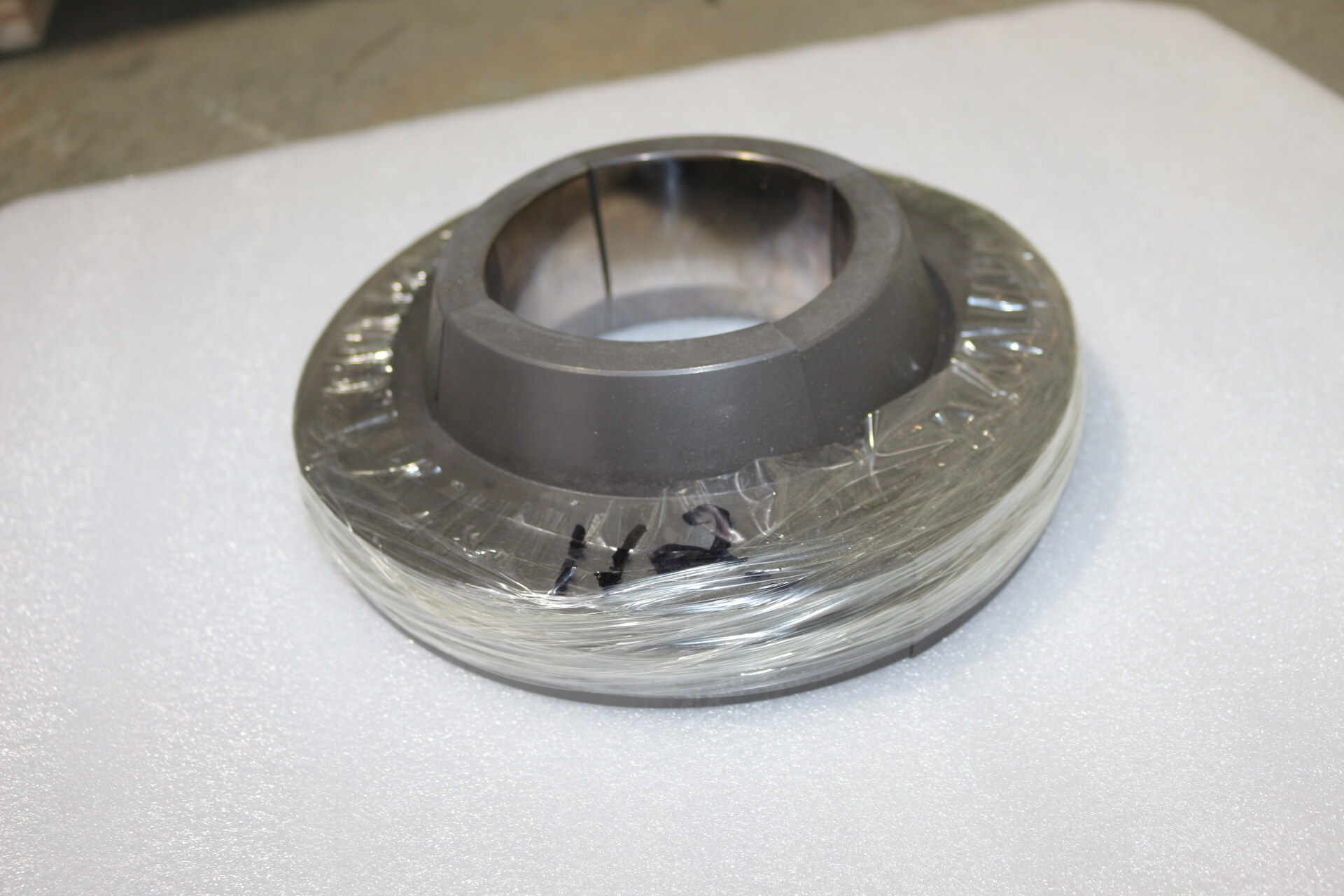

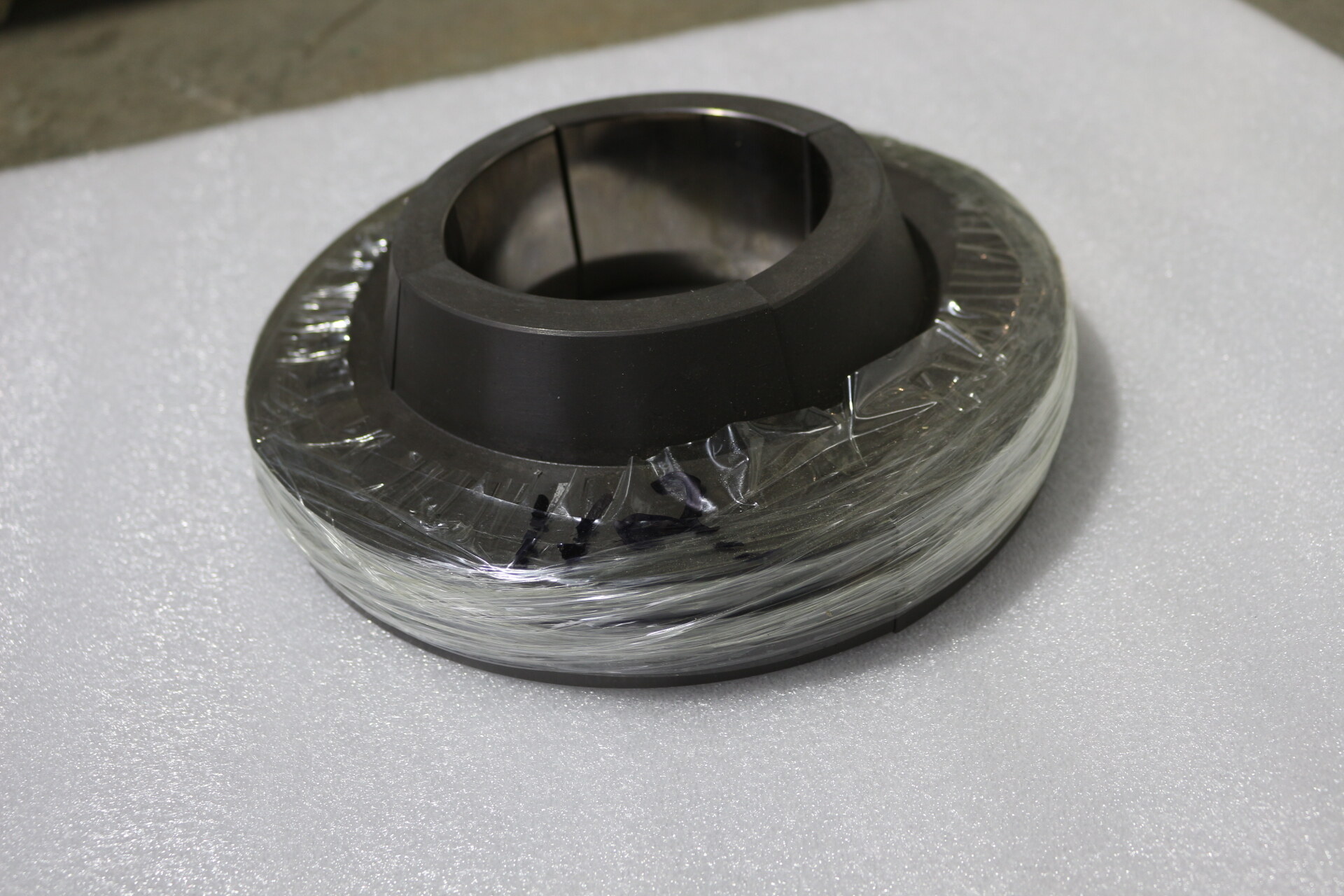

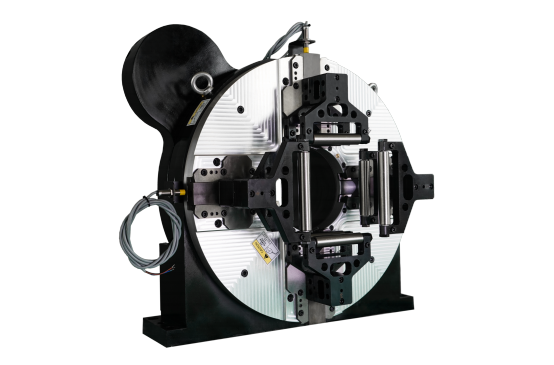

Hollow Pneumatic Rotary Chuck

A tapping chuck called a hollow pneumatic rotary chuck is used on machine machines to clamp taps while internally threaded holes are being processed. Tap chucks, chuck jackets, compression springs, steel balls, and tap jackets make up the majority of its parts.

Hollow Pneumatic Rotary Chuck

Hollow Pneumatic Rotary Chuck is a tapping chuck used for clamping taps on machine tools to process internally threaded holes. It is mainly composed of tap chucks, chuck jackets, compression springs, steel balls, and tap jackets.

The features of Hollow Pneumatic Rotary Chuck

The end surface of the chuck jacket is provided with claws that engage with the machine tool spindle, and the handle of the chuck jacket is equipped with steel balls, springs, and pressure rollers that can not only transmit power to the tapping chuck but also play the role of overload protection. Tighten the screws. The structure is simple and reasonable, most of the parts adopt standard parts, and the processing accuracy of special-shaped parts is not high, which greatly reduces the manufacturing cost. The spring force adjustment of the overload protection does not require special tools, and the overload protection is reliable.

The advantages of Hollow Pneumatic Rotary Chuck

- Clamping quickly improves work efficiency

- Reduce labor intensity and improve corporate image

- Simple structure and easy installation

- No need to use consumables to invest in one step

- Large clamping force and wide clamping range

- High clamping precision and long service life

- Strong safety and reliability

The maintenance of Hollow Pneumatic Rotary Chuck

- Do not dismantle the parts of the tool arbitrarily before operating, except that it will affect the safety of the operator and cause damage to the tool.

- If the tool is slightly faulty or cannot achieve the original function after use, it should not be used any longer and should be checked immediately.

- Regularly (about once a week) check and maintain tools, add grease (Grease) to bearings and other rotating parts, and add oil (Oil) to air motor parts.

- When using various tools, be sure to follow various safety regulations and instructions for use.

- It is necessary to choose appropriate tools for work. Too large tools may cause work injuries, and too small tools may cause tool damage.