Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

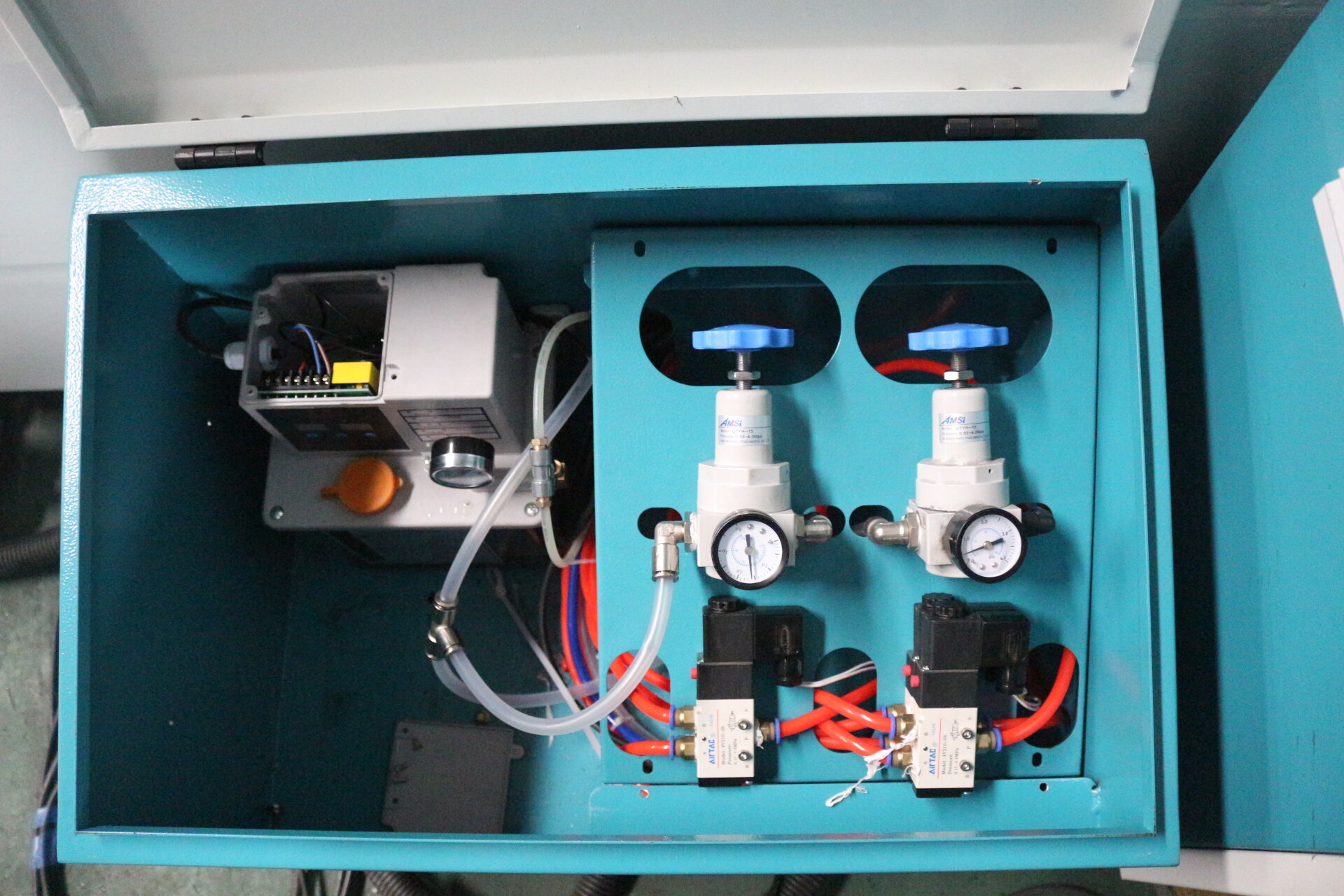

Automatic Oil Supply System

A motor-driven gear pump drives the automated lubricating pump. Incorporating a controller of the "MY" type, an automatic emptying valve, a switch for the liquid level, etc. It is a pump that operates sporadically. For a volumetric quantitative centralized lubrication system that requires routine maintenance. Power up so that it can begin operating automatically. It contains features including an output joint control signal and a liquid level alarm.

Automatic Oil Supply System

The automatic lubrication pump is a motor-driven gear pump. Including an "MY" type controller, automatic unloading valve, liquid level switch, etc. It is an intermittent working pump. It is used for a volumetric quantitative centralized lubrication system that needs periodic work. Turn on the power, it can work automatically. It has functions such as a liquid level alarm and output joint control signal.

The Use and Adjust of Automatic Oil Supply System

- Applicable ambient temperature for lubricating pump: -5℃~40℃; lubricating medium: N32#~N68# lubricating oil.

- Clean lubricating oil should be added each time. When refueling, open the refueling cap and inject through the refueling filter. The amount added should be within the range of the oil level line of the fuel tank. The fuel tank must be cleaned every six months, and the refueling filter and oil pump suction filter should be cleaned or replaced at the same time.

- The oil pump should be installed horizontally, and should try to avoid using it in an environment with corrosive gas, dust, and high humidity.

- The pump panel is equipped with three indicator lights for power supply, work, and low liquid level, an intermittent time adjustment knob, and a jog button.

- Turn on the power, and the power indicator light is on. Adjust the intermittent time knob to an appropriate value first, which can be corrected according to the actual situation during debugging. The oil pump enters the automatic working state. When pumping oil, the working indicator light is on. When the oil pump is finished, it enters the intermittent timing state; when the "intermittent time" is completed, it enters the next working cycle, and it goes round and round until the power is cut off. The pumping time is set. Press "jog lubrication", that is, pump oil. Stop pumping oil, and the system pressure will be unloaded automatically.

- The system pressure is controlled by a pressure-regulating valve. Turn the pressure valve adjustment screw clockwise to increase the pressure; otherwise, the pressure will decrease. All have been adjusted (1.8MPa) and locked before leaving the factory. Users generally do not adjust at will.