Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

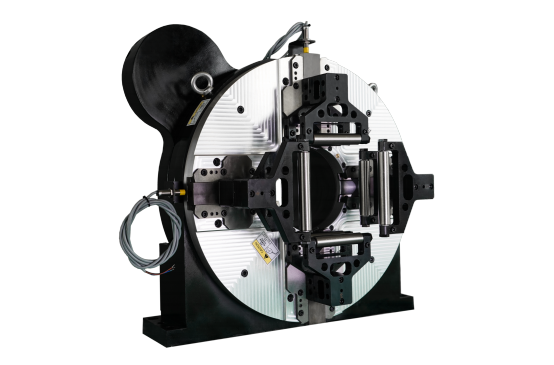

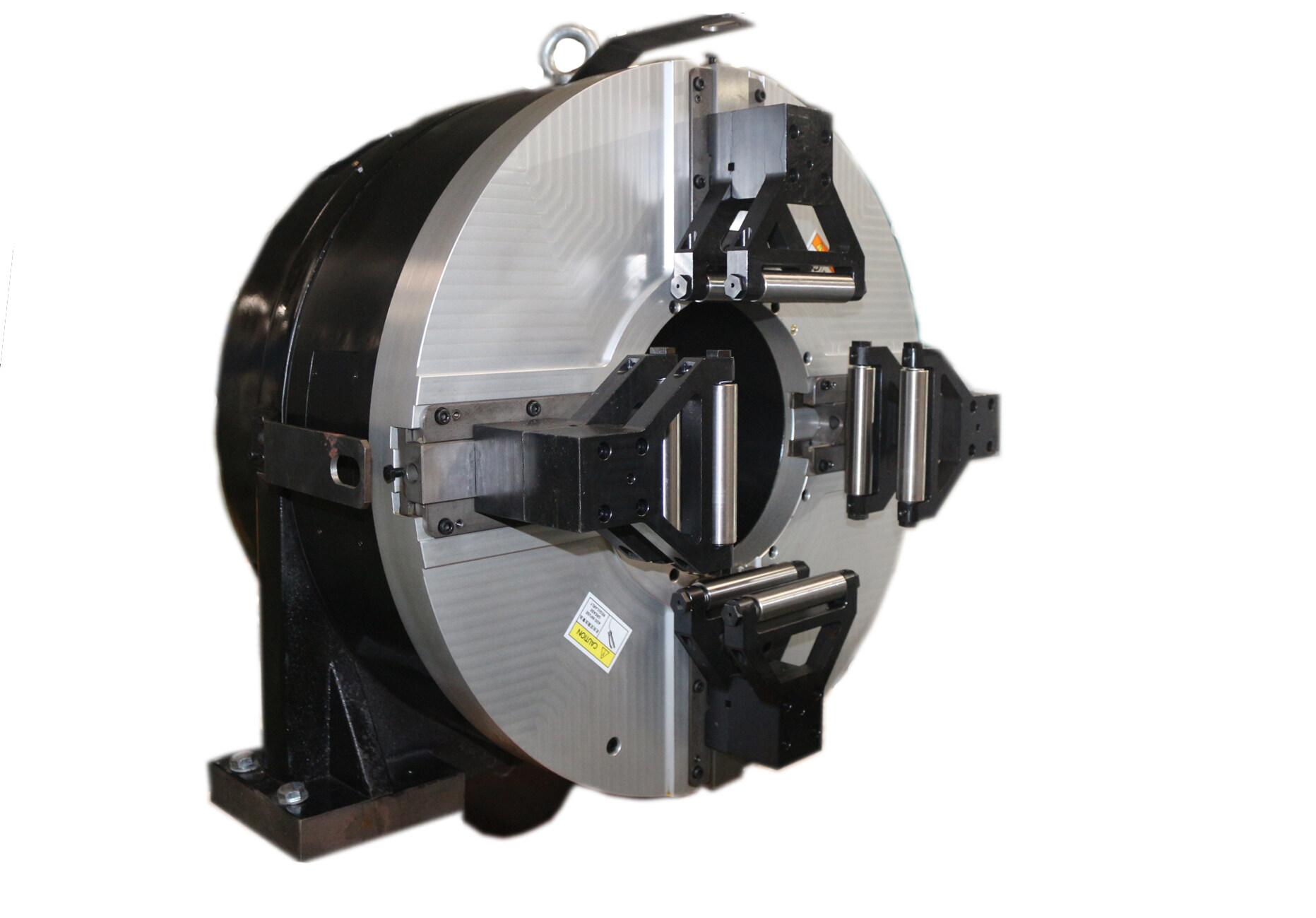

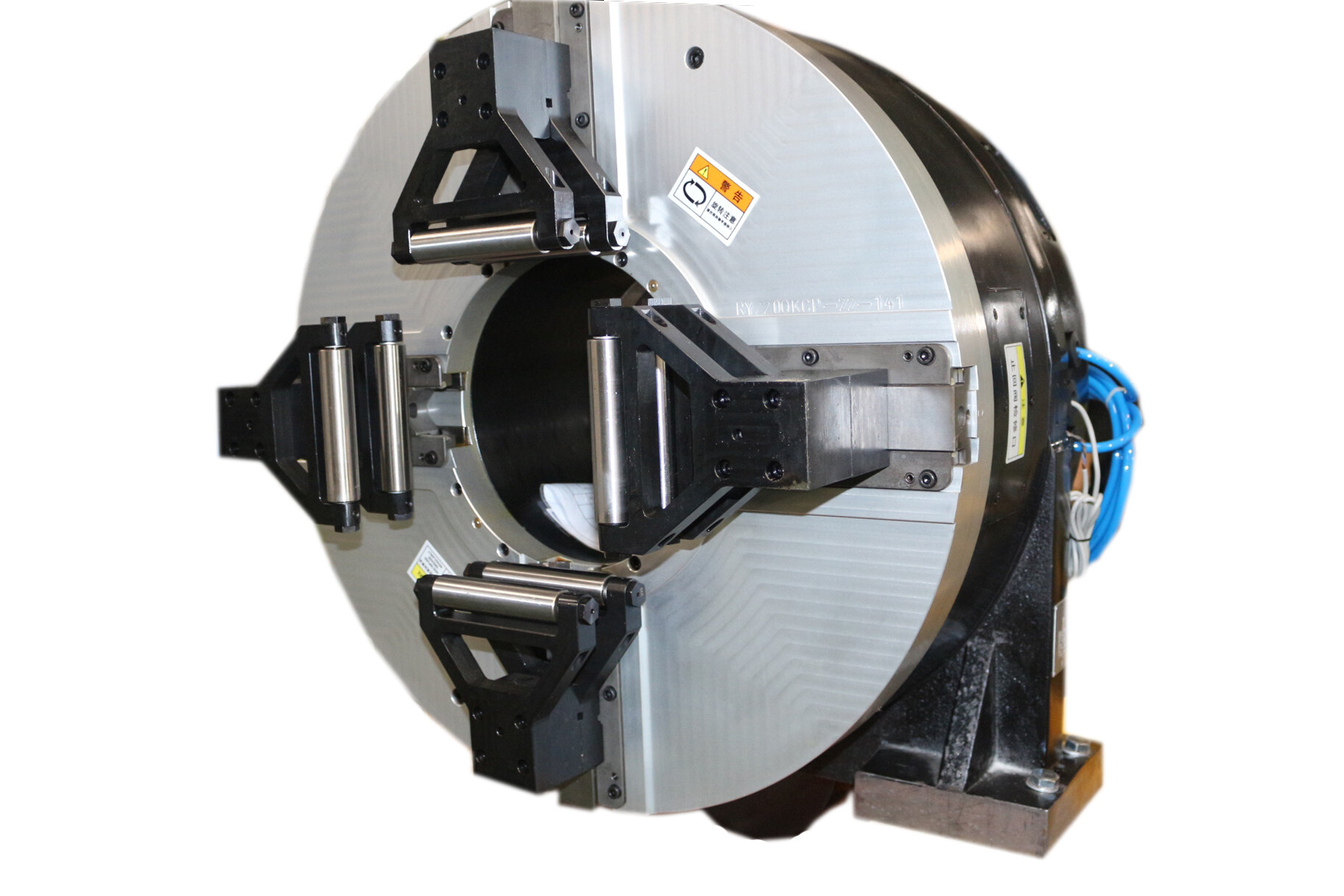

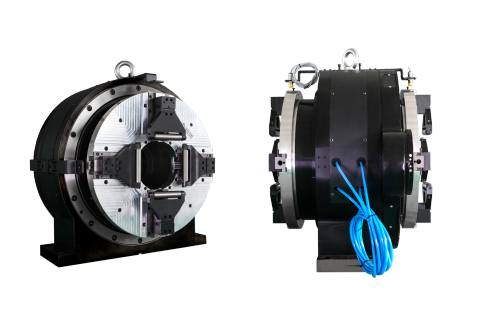

Pneumatic Double Chuck

The uniformly spaced movable jaws on the chuck body of the laser pneumatic chuck move radially to clamp and position the workpiece. The moving jaw, the transmission mechanism for the moving jaw, and the chuck body normally make up the laser pneumatic chuck.

Pneumatic Double Chuck

The laser pneumatic chuck clamps and positions the workpiece through the radial movement of the movable jaws evenly distributed on the chuck body. The laser pneumatic chuck is generally composed of the chuck body, the movable jaw, and the jaw transmission mechanism. The laser pneumatic chuck has a hole in the center to pass through the workpiece or bar; the back has a cylindrical or short conical structure, directly or through the flange and the end of the machine tool spindle. Laser pneumatic chucks are usually installed on lathes, external grinding machines, and internal grinding machines. It can also be used in conjunction with various indexing devices such as milling machines and drilling machines.

The features of Pneumatic Double Chuck

- Compared with ordinary chucks, the working efficiency of pneumatic chucks will be greatly improved, such as in clamping. And the practical life will be much longer than that.

- The structure of the pneumatic chuck is very, very simple, without those cumbersome and complicated components, so the installation is very convenient and labor-saving, and it is not easy to cause mistakes.

- In terms of consumable energy, it can be called no consumption. Moreover, it is environmentally friendly and has no pollution, which is a practical and superb advantage in today's increasingly aggravated environmental pollution.

- In the machinery industry, everyone knows that safety is the most important item. Therefore, the pneumatic chuck has strict factory inspections, pressure tests, and error tests, all of which are zero-risk. Therefore, the pneumatic chuck can be accepted and used by the majority of users in the field.

The maintenance of Pneumatic Double Chuck

- The laser pneumatic chuck should be maintained and maintained at the same time as the machine tool;

- During the use of the chuck, it must be lubricated (at the oil cup) and cleaned (with compressed air) every shift to maintain the accuracy of the chuck and prolong its service life;

- The chuck should be thoroughly cleaned, lubricated, and maintained at least twice a year, as well as the treatment of dangerous parts, and all working surfaces should be lubricated. When the frequency of use of the machine tool increases or the environment is under special conditions, the frequency of cleaning, lubrication, and other parts of the chuck should be appropriately increased.