Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Please enter the email address you’d like your password reset information sent to.

Email format error

Email cannot be empty

Email does not exist

Reset account password

For the account

6-20 characters(letters plus numbers only)

The password is inconsistent

Reset success

Your password was reset. You can log in using your new password.

Login

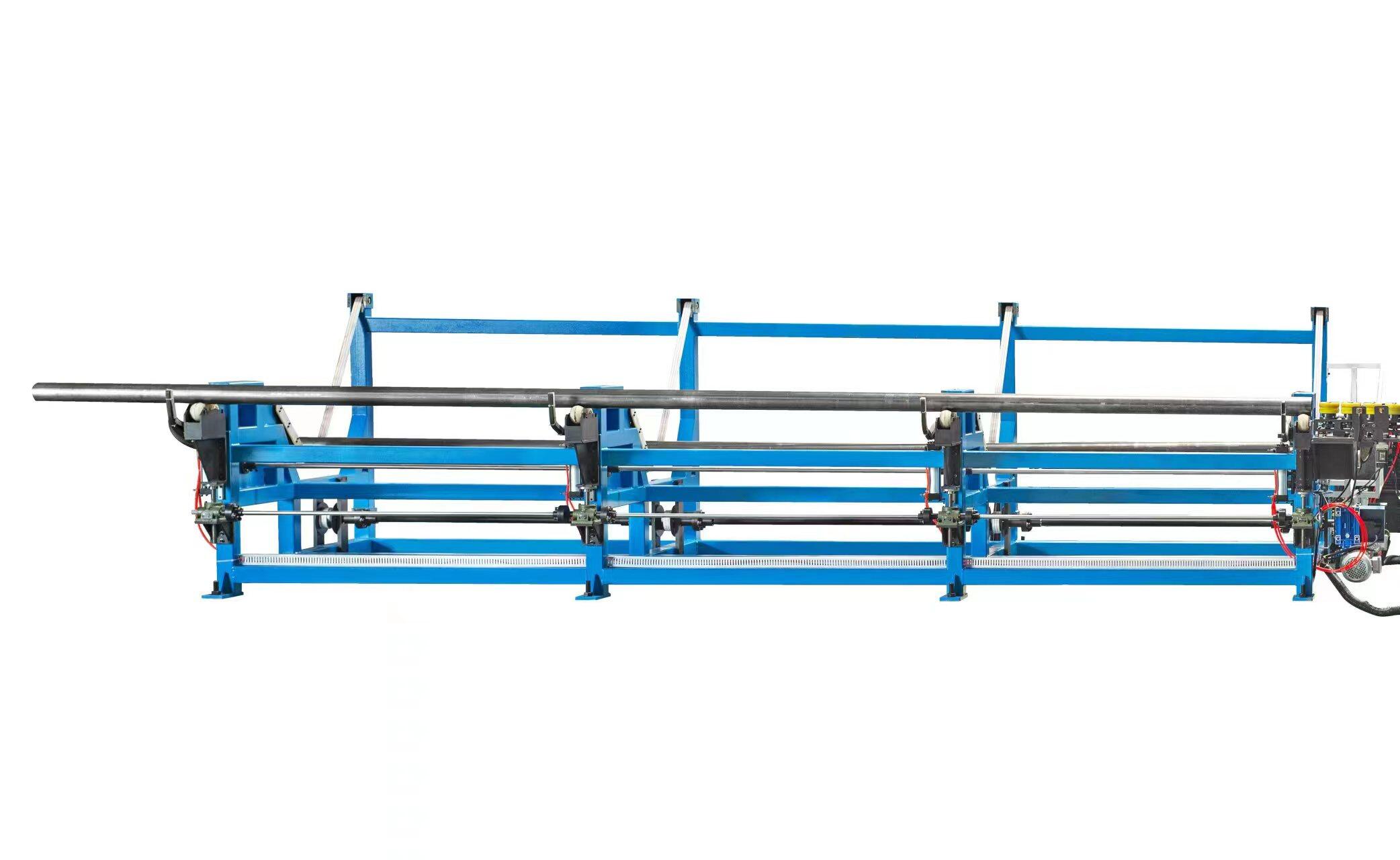

Fully automatic loading rack

Fully automatic loading rack

A newly created feeding rack for supporting the laser cutting machine is the fully automatic loading rack. It has high efficiency, consistent feeding, and complete automatic control.

Contact us

Inquiry Basket

OEM:

Available

Sample:

Available

Payment:

T/T

Place of Origin:

China

Supply Ability:

200000 piece per Month

Fully automatic loading rack

The fully automatic loading rack is a newly developed feeding rack for supporting the laser cutting machine. It is fully automatically controlled, with stable feeding and high efficiency.

The Workflow of Fully automatic loading rack

- Pipe into the stack: Bundles of pipes are hoisted into the stack, cut the bundled rope, and wait for loading;

- Power-on reset: Turn on the power supply, and all components start to reset;

- Pipe sling pull tube loading: the motor drives the main shaft of the sling, the sling rolls up, pulls up the pipes in the material stack, and sends them to the pipe support channel, and the stop bar intercepts the pipes;

- The pipes fall onto the support channel, and the single-tube rejecting mechanism removes excess pipes, leaving only one pipe on the support channel;

- Single tube rejecting mechanism: the up and down drive motor drives the insert plate down to a certain position, the front and rear drive motor drives the insert plate to move laterally to a certain position, and kicks the pipe back to the material stack;

- When there is only one pipe on the supporting material channel, the action of the inserting plate pushes the pipe to the pipe lifting position;

- Roller lifting: When the pipe moves to the roller lifting mechanism, the lifting cylinder is stretched out, and the pipe is lifted to the target position;

- Pipe pushing and length measurement: Since the pipes to be cut may be of different lengths, the position of the pipes must be adjusted before being sent to the laser pipe-cutting machine, and the actual length shall be measured, so the length measurement shall be pushed;

- Clamping and feeding: After the adjustment and measurement of the pipe position is completed, the clamping and feeding mechanism acts to pick up the pipe and send it to the target position of the laser pipe cutting machine;

- The laser pipe cutting machine clamps the pipe and completes the cutting.

Contact us