Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

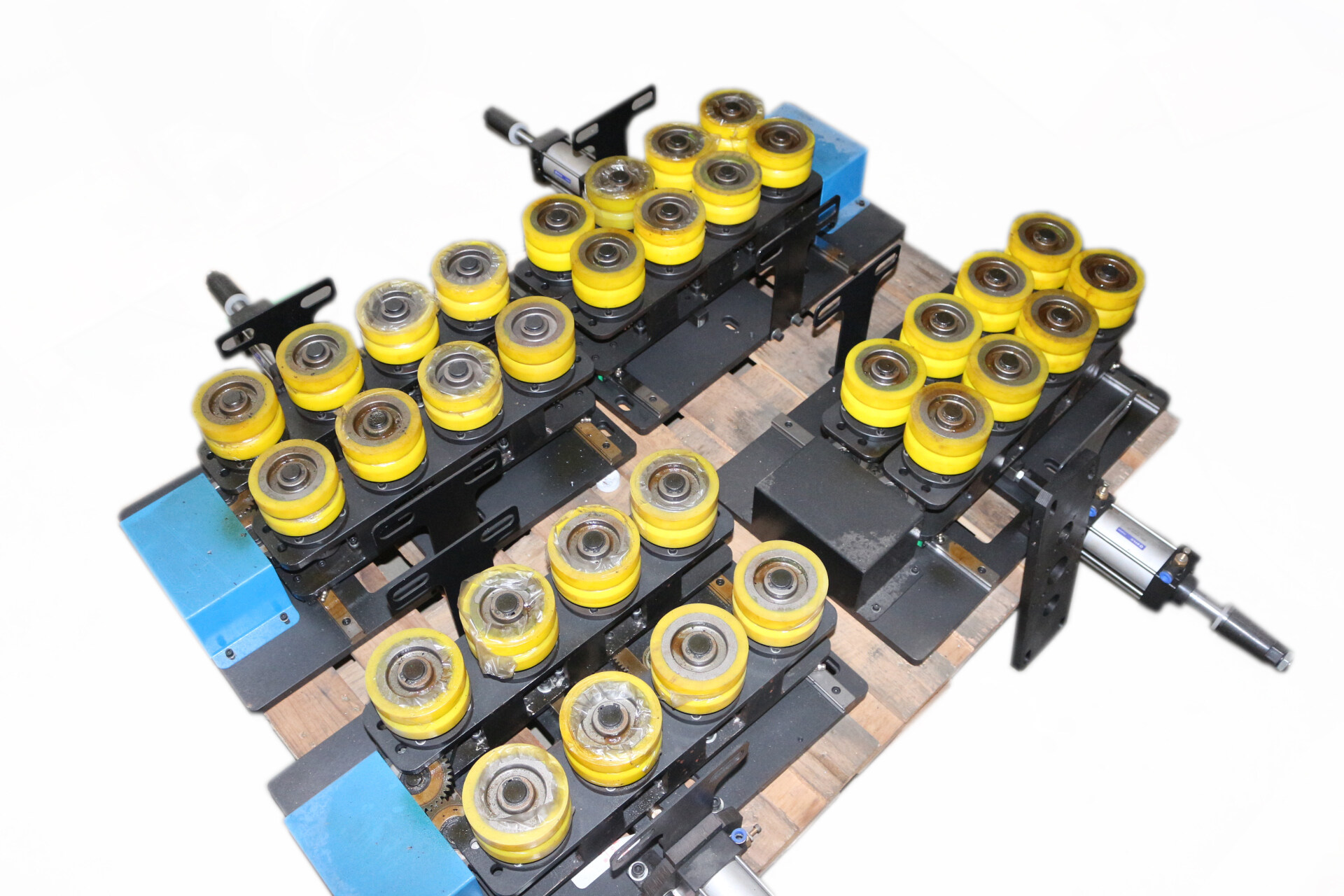

Centering feeding wheel

Introducing the Centering Feeding Wheel, a revolutionary tool designed to enhance precision and efficiency in your manufacturing process. This innovative device ensures accurate alignment and smooth feeding of materials, eliminating errors and reducing downtime. Experience seamless operations and improved productivity with the Centering Feeding Wheel.

Centering feeding wheel

Our centering feeding wheel feeds stably, bites tightly, and is super wear-resistant. It is recommended to replace the original one after a period of use to avoid loose bite and maintain higher printing quality.

The features of Centering feeding wheel

- One-way bearing

a. Embedded with super hard alloy and matched with liquid column bearing, it has wear resistance, safety, high precision, and long life.

b. Gears are heat-treated at HRC60℃ and then precision ground, with high transmission precision.

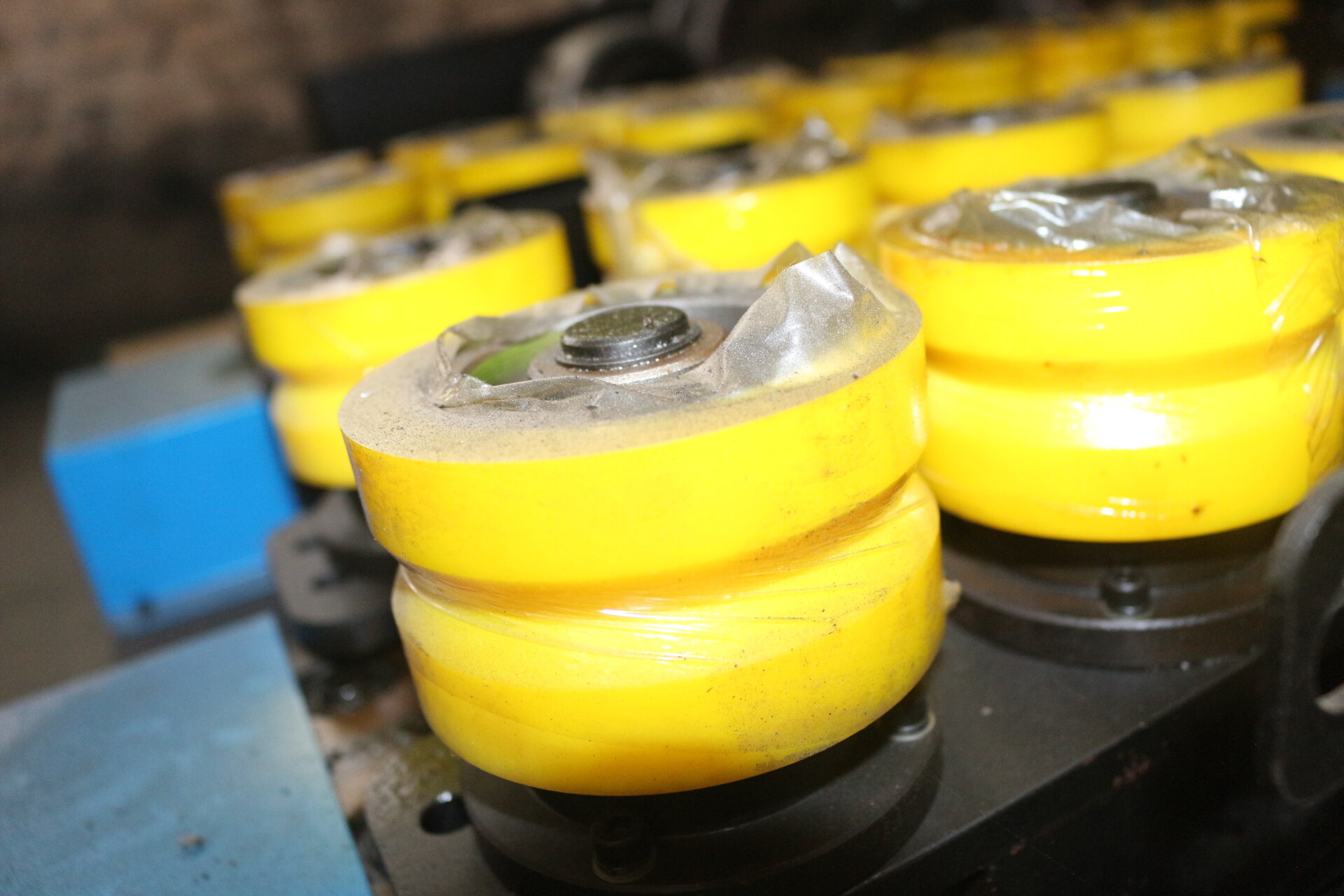

- Roller

a. It adopts a hollow type, is lightweight, has small rotary inertia, and can stop immediately to ensure feeding accuracy.

b. After heat treatment HRC60° hard chrome plating and then grinding, it has high hardness, excellent wear resistance, and long service life.

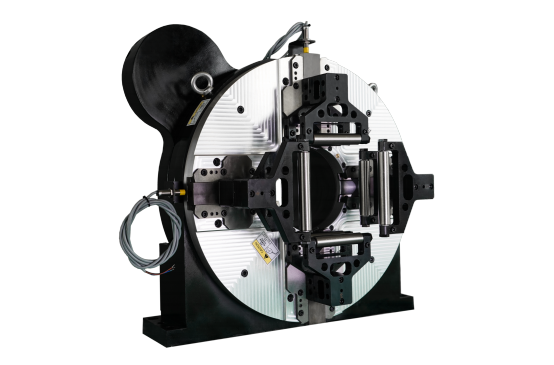

3. Disc brake (general brake device)

A high-grade clutch is used to make the two sides of the plate fully contact, with long service life, good stability, and high precision.

- Reverse device

a. The structure is the same as that of the one-way device. It can control the lower wheel quite accurately. It will not cause the lower wheel to retreat even if it is used for a long time, and the stability accuracy is quite high.

b. The brakes will not fail due to the residual oil splashed during stamping, causing the lower wheel to reverse and the feeding distance to be inaccurate.

c. It is not easy to generate high fever.

d. Attached with super hard alloy and roller, not easy to wear.

e. The action mode is the circular motion of the rollers, rather than the linear motion of the four guide pillars, so there will be no seizure phenomenon.

f. The friction force is small, the required transmission torque is relatively reduced, and the transmission mechanism is less likely to be damaged.

g. If equipped with a reverse device, the speed can reach 30 m/min, generally 20 m/min, which increases the efficiency by 50%.

h. Special structure increases service life.

Why Choose Us?

Your Partner for OEM Centering Feeding Wheel Solutions:As a leading OEM centering feeding wheel manufacturer, we offer custom-engineered solutions to fit your unique needs. We work closely with OEMs to develop feeding wheels that integrate seamlessly with their equipment.

Tailored Design: Our engineering team can design OEM centering feeding wheels to your exact specifications.

Quality Assurance: We adhere to strict quality control measures to ensure that every OEM centering feeding wheel meets our high standards.

Expert Support: Our knowledgeable staff is available to provide support and answer any questions you may have about our OEM solutions.