Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Please enter the email address you’d like your password reset information sent to.

Email format error

Email cannot be empty

Email does not exist

Reset account password

For the account

6-20 characters(letters plus numbers only)

The password is inconsistent

Reset success

Your password was reset. You can log in using your new password.

Login

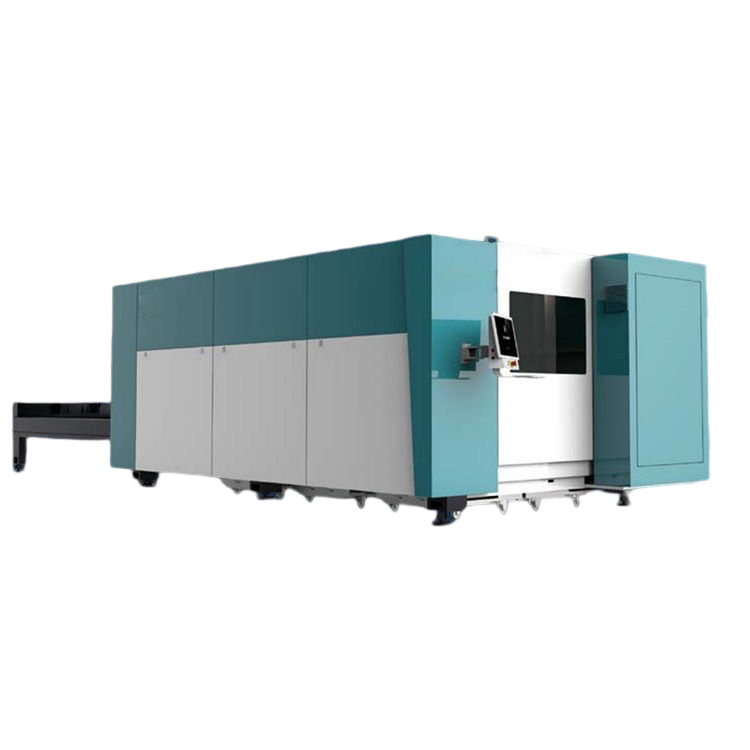

The Power of Precision: 2500W Aluminum Laser Cutting Machine Factories

2023-11-28 17:54:51

The realm of manufacturing has been revolutionized by the advent of laser cutting technology, with the 2500W aluminum laser cutting machine standing at the forefront of this industrial evolution. These powerful machines have become pivotal in various sectors, offering unmatched precision and efficiency. This blog will explore the capabilities, applications, and future of 2500W aluminum laser cutting machine factories.

Understanding 2500W Aluminum Laser Cutting Machines

A 2500W laser cutter is a formidable tool, boasting a power output that allows it to slice through aluminum with ease. This power level not only enhances cutting speed but also expands the range of materials that can be processed, including thicker and more robust metals.

Aluminum’s unique properties, such as its lightweight nature and excellent conductivity, make it an ideal candidate for laser cutting. The use of aluminum in manufacturing is beneficial due to its versatility and the high-quality finish it provides to the final product.

Key Features of 2500W Laser Machines in Factories

Precision is paramount in laser cutting, and 2500W machines achieve this through advanced optics and control systems. Accuracy is not just about hitting the right measurements; it’s about ensuring repeatability and consistency across large production runs.

When compared to traditional cutting methods, 2500W laser cutters are significantly faster, directly impacting production timelines and throughput. This speed does not come at the expense of quality, making these machines highly efficient.

The adaptability of 2500W laser cutters allows them to handle a wide array of materials beyond aluminum, including steel, copper, and brass. This versatility makes them invaluable to factories that cater to diverse industries.

The Manufacturing Process in 2500W Laser Cutting Machine Factories

The design phase is streamlined with software that translates intricate designs into precise cutting instructions. Prototyping with a 2500W laser cutter is swift, enabling rapid iteration and development.

The production process in factories equipped with 2500W laser cutters is a marvel of modern manufacturing. Quality control is embedded at every stage, ensuring that each component meets stringent standards.

After cutting, additional processes such as bending, welding, or painting may be required. The finishing touches are crucial for the aesthetic and functional quality of the final product.

Applications of 2500W Aluminum Laser Cutting Machines

In industries where precision is non-negotiable, such as aerospace and automotive, 2500W laser cutters are indispensable. They are used to create complex parts that meet exact specifications and can be customized for unique applications.

From structural components to decorative elements, the construction and architecture sectors rely on the precision of laser cutting. The ability to work with large sheets of metal makes these machines particularly useful in these industries.

The trend towards miniaturization in electronics and appliances has increased the demand for precise manufacturing methods. 2500W laser cutters play a critical role in producing the intricate components required in these devices.

Selecting the Right 2500W Laser Cutting Machine Factory

When selecting a factory, consider its reputation, reliability, and the level of technical support and service it offers. These factors will significantly influence the success of your projects.

A factory that offers customization and is willing to collaborate closely with clients can provide tailored solutions that meet specific needs. This collaborative approach is essential for innovative designs and applications.

The cost-benefit ratio of investing in services from a 2500W laser cutting machine factory should be carefully analyzed. The initial investment is often offset by long-term savings and productivity gains.

Safety and Maintenance in Operating 2500W Laser Cutters

Operating high-power laser equipment requires strict safety protocols and comprehensive training to ensure operator safety. Factories must equip their machines with mandatory safety features to prevent accidents.

Regular maintenance is crucial for the longevity and performance of laser cutting machines. A well-maintained machine minimizes downtime and maintains cutting precision.

Future Trends in Laser Cutting Technology

The future of laser cutting technology is bright, with ongoing advancements in laser power, efficiency, and the integration of automation and AI. These innovations promise to further enhance the capabilities of laser cutting machines.

As environmental concerns become more pressing, the focus on energy consumption and eco-friendly practices in laser cutting is intensifying. Efforts to reduce material waste and promote recycling are becoming increasingly important.

The 2500W aluminum laser cutting machine has transformed the manufacturing landscape, offering unparalleled precision, speed, and versatility. As we look to the future, the continued innovation in laser cutting technology will undoubtedly lead to even more impressive achievements in manufacturing and production. The potential for these machines to drive industry forward is immense, and embracing these advancements will be key to staying competitive in a rapidly evolving market.

We are a leading 2500w aluminum laser cutting machine factory. If you have any questions, feel free to contact us.

Understanding 2500W Aluminum Laser Cutting Machines

Technical specifications of 2500W laser cutters

A 2500W laser cutter is a formidable tool, boasting a power output that allows it to slice through aluminum with ease. This power level not only enhances cutting speed but also expands the range of materials that can be processed, including thicker and more robust metals.

The role of aluminum in laser cutting

Aluminum’s unique properties, such as its lightweight nature and excellent conductivity, make it an ideal candidate for laser cutting. The use of aluminum in manufacturing is beneficial due to its versatility and the high-quality finish it provides to the final product.

Key Features of 2500W Laser Machines in Factories

Precision and Accuracy

Precision is paramount in laser cutting, and 2500W machines achieve this through advanced optics and control systems. Accuracy is not just about hitting the right measurements; it’s about ensuring repeatability and consistency across large production runs.

Speed and Efficiency

When compared to traditional cutting methods, 2500W laser cutters are significantly faster, directly impacting production timelines and throughput. This speed does not come at the expense of quality, making these machines highly efficient.

Versatility and Adaptability

The adaptability of 2500W laser cutters allows them to handle a wide array of materials beyond aluminum, including steel, copper, and brass. This versatility makes them invaluable to factories that cater to diverse industries.

The Manufacturing Process in 2500W Laser Cutting Machine Factories

Design and Prototyping

The design phase is streamlined with software that translates intricate designs into precise cutting instructions. Prototyping with a 2500W laser cutter is swift, enabling rapid iteration and development.

Production and Assembly

The production process in factories equipped with 2500W laser cutters is a marvel of modern manufacturing. Quality control is embedded at every stage, ensuring that each component meets stringent standards.

Post-Processing and Finishing

After cutting, additional processes such as bending, welding, or painting may be required. The finishing touches are crucial for the aesthetic and functional quality of the final product.

Applications of 2500W Aluminum Laser Cutting Machines

Aerospace and Automotive Industries

In industries where precision is non-negotiable, such as aerospace and automotive, 2500W laser cutters are indispensable. They are used to create complex parts that meet exact specifications and can be customized for unique applications.

Construction and Architecture

From structural components to decorative elements, the construction and architecture sectors rely on the precision of laser cutting. The ability to work with large sheets of metal makes these machines particularly useful in these industries.

Consumer Electronics and Appliances

The trend towards miniaturization in electronics and appliances has increased the demand for precise manufacturing methods. 2500W laser cutters play a critical role in producing the intricate components required in these devices.

Selecting the Right 2500W Laser Cutting Machine Factory

Factors to Consider When Choosing a Factory

When selecting a factory, consider its reputation, reliability, and the level of technical support and service it offers. These factors will significantly influence the success of your projects.

Customization and Collaboration

A factory that offers customization and is willing to collaborate closely with clients can provide tailored solutions that meet specific needs. This collaborative approach is essential for innovative designs and applications.

Cost-Effectiveness and ROI

The cost-benefit ratio of investing in services from a 2500W laser cutting machine factory should be carefully analyzed. The initial investment is often offset by long-term savings and productivity gains.

Safety and Maintenance in Operating 2500W Laser Cutters

Safety Protocols and Training

Operating high-power laser equipment requires strict safety protocols and comprehensive training to ensure operator safety. Factories must equip their machines with mandatory safety features to prevent accidents.

Routine Maintenance and Upkeep

Regular maintenance is crucial for the longevity and performance of laser cutting machines. A well-maintained machine minimizes downtime and maintains cutting precision.

Future Trends in Laser Cutting Technology

Innovations on the Horizon

The future of laser cutting technology is bright, with ongoing advancements in laser power, efficiency, and the integration of automation and AI. These innovations promise to further enhance the capabilities of laser cutting machines.

Sustainability and Environmental Considerations

As environmental concerns become more pressing, the focus on energy consumption and eco-friendly practices in laser cutting is intensifying. Efforts to reduce material waste and promote recycling are becoming increasingly important.

Conclusion

The 2500W aluminum laser cutting machine has transformed the manufacturing landscape, offering unparalleled precision, speed, and versatility. As we look to the future, the continued innovation in laser cutting technology will undoubtedly lead to even more impressive achievements in manufacturing and production. The potential for these machines to drive industry forward is immense, and embracing these advancements will be key to staying competitive in a rapidly evolving market.

We are a leading 2500w aluminum laser cutting machine factory. If you have any questions, feel free to contact us.

Contact us