Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

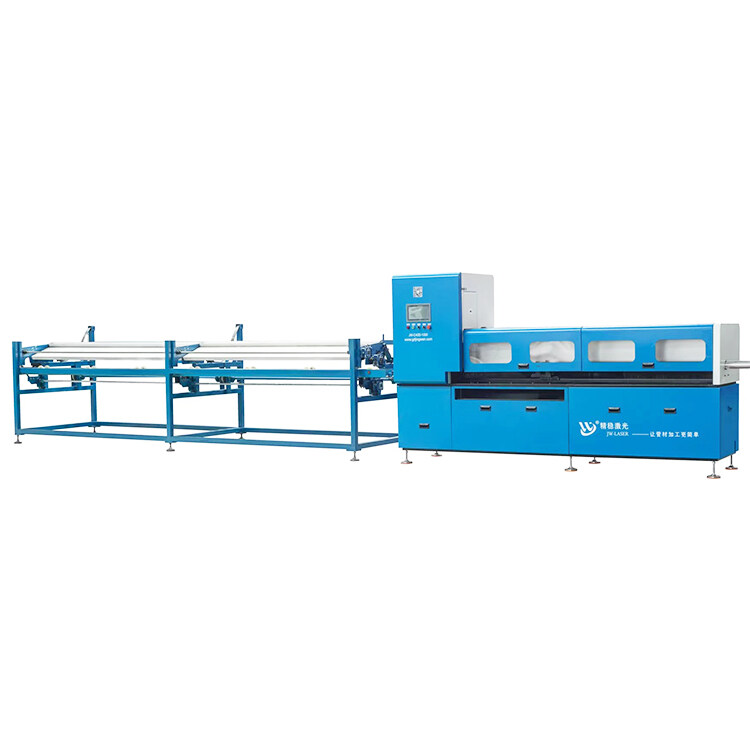

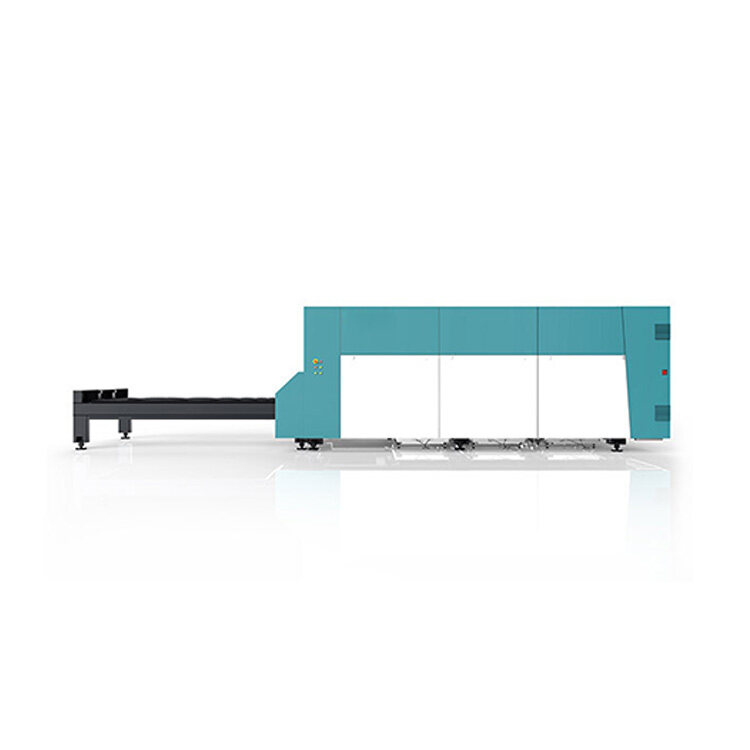

C250D aluminum round pipe laser cutting machine

Several application scenarios for the round pipe laser cutting machine result in a diversity of tube shapes, which raises the bar for the metal tube cutting process. When compared to conventional cutting, laser cutting is flexible, doesn't require opening molds, saves a lot of time developing new products, is quick and precise, and can be used to cut holes in pipes as well as cut lines and use conventional ways. precise cutting of numerous difficult-to-achieve special-shaped and intricate artwork.

Key Features - China Aluminum Pipe Laser Cutting Machine

1. High-Precision Laser Cutting: The pipe laser cutting machine employs a high-power fiber laser source that generates a focused and concentrated laser beam. This ensures exceptional cutting precision, allowing for intricate designs and precise contours on aluminum round pipes.

2. Versatility: The machine is optimized for cutting aluminum round pipes of various diameters and thicknesses. Whether it's thin-walled or thick-walled pipes, the aluminum pipe laser cutting machine handles them with ease, making it a versatile tool for various applications.

3. Automatic Pipe Loading and Unloading: Many models of the machine come equipped with an automatic pipe loading and unloading system. This feature streamlines the cutting process, reducing manual labor and increasing overall productivity.

4. 3D Cutting Capability: The machine boasts 3D cutting capabilities, enabling it to cut complex shapes and bevels on aluminum round pipes, catering to the diverse needs of the metal fabrication industry.

5. User-Friendly Interface: The machine is equipped with an intuitive control system, making it easy to operate and program. This user-friendly interface allows operators to set cutting parameters and switch between different cutting tasks with minimal effort.

6. Advanced Nesting Software: The pipe laser cutting machine often comes with powerful nesting software that optimizes material usage, reducing waste and enhancing production efficiency.

Applications - China Aluminum Pipe Laser Cutting Machine

The China aluminum round pipe laser cutting machine finds applications in various industries, including:

- Construction: For precise cutting and fabrication of aluminum pipes used in building structures and architectural elements.

- Furniture: To create customized aluminum pipe components for high-end furniture and interior design.

- Automotive: For manufacturing exhaust systems and other aluminum pipe components used in the automotive industry.

- Aerospace: In the production of lightweight, precision aluminum parts for aircraft and aerospace applications.

As a leading player in the industry, Jingwen continues to innovate and offer cutting-edge solutions like the laser cutting machine for aluminum pipe. With its precision, efficiency, and versatility, this machine empowers industries to meet the growing demand for high-quality aluminum round pipe products.

Operation precautions - China Aluminum Pipe Laser Cutting Machine

- Wear labor protective equipment according to the regulations, and must wear protective glasses that meet the regulations near the laser beam.

- Do not process material before it is clear whether it can be irradiated or heated by a laser, to avoid the potential danger of smoke and steam.

- When the laser cutting machine is started, the operator is not allowed to leave the post without authorization or ask someone to take care of it.

- Put the fire extinguisher within easy reach and do not place paper, cloth, or other flammable materials near the unprotected laser beam.

- When the laser equipment is found to be abnormal during processing, it should be shut down immediately, and the fault should be eliminated in time or reported to the supervisor.

- Keep the laser, bed, and the surrounding area clean, orderly, and free of oil, and the workpieces, plates, and waste materials should be piled up according to regulations.

- Every 40 hours of operation or weekly maintenance, every 1000 hours of operation, or every six months of maintenance must be carried out by regulations and procedures.

Jingwen - China Aluminum Pipe Laser Cutting Machine Factory

Jingwen is a renowned China-based aluminum pipe laser cutting machine factory, specializing in the design, production, and distribution of high-quality laser cutting equipment for the aluminum pipe processing industry. With a strong commitment to innovation, precision, and customer satisfaction, Jingwen has become a leading player in the field of laser cutting technology.

1. Expertise in Laser Technology: With years of experience and expertise in laser technology, Jingwen's engineers and technicians are well-equipped to develop cutting-edge laser cutting machines tailored specifically for the aluminum pipe industry.

2. Customized Solutions: We recognizes that each customer's requirements are unique. We offer customized solutions to meet the diverse needs of their clients. From laser power options and cutting bed sizes to automation systems and software enhancements, Jingwen ensures that their machines align perfectly with the customer's specific demands.

3. Precision and Efficiency: Jingwen's aluminum pipe laser cutting machines are equipped with high-power fiber laser sources that deliver precise and efficient cutting results. This technology allows for clean and accurate cuts with minimal heat-affected zones, ensuring superior quality and reducing material waste.

4. Wholesale services: Jingwen offers a wide range of wholesale aluminum pipe laser cutting machines, delivering precision and efficiency for various industrial applications. With advanced technology and customizable features, we wholesale aluminum pipe laser cutting machines at affordable prices for meeting the needs of every business.

5. Advanced Software: Our metal pipe cutting laser machines are accompanied by advanced nesting software that optimizes material usage, resulting in reduced waste and increased cost-effectiveness.

6. Comprehensive Support: Jingwen is dedicated to providing comprehensive support to its customers. From initial training and installation to ongoing technical assistance and maintenance, their team of professionals ensures that customers can maximize the potential of their machines.

7. Quality and Commitment: Our aluminum pipe laser cutting machines undergo rigorous testing and adhere to international standards to guarantee exceptional performance and durability. Our company's commitment to excellence, combined with our continuous efforts in research and development, allows them to stay at the forefront of laser cutting technology.

As a customer-centric company, Jingwen aims to build long-term partnerships with its clients. By providing reliable, efficient, and customized solutions, Jingwen empowers industries to enhance their production capabilities and achieve remarkable results in the aluminum pipe processing sector.

Jingwen aluminum pipe laser cutting machine factory is your trusted partner for precision cutting solutions and a driving force in the advancement of the aluminum pipe processing industry.