Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

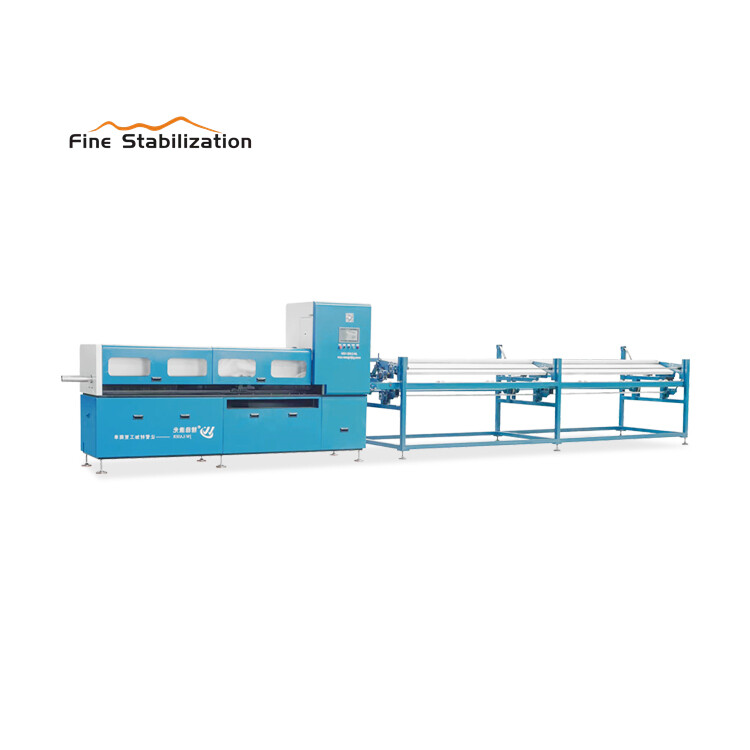

C90D carbon steel round pipe laser cutting machine

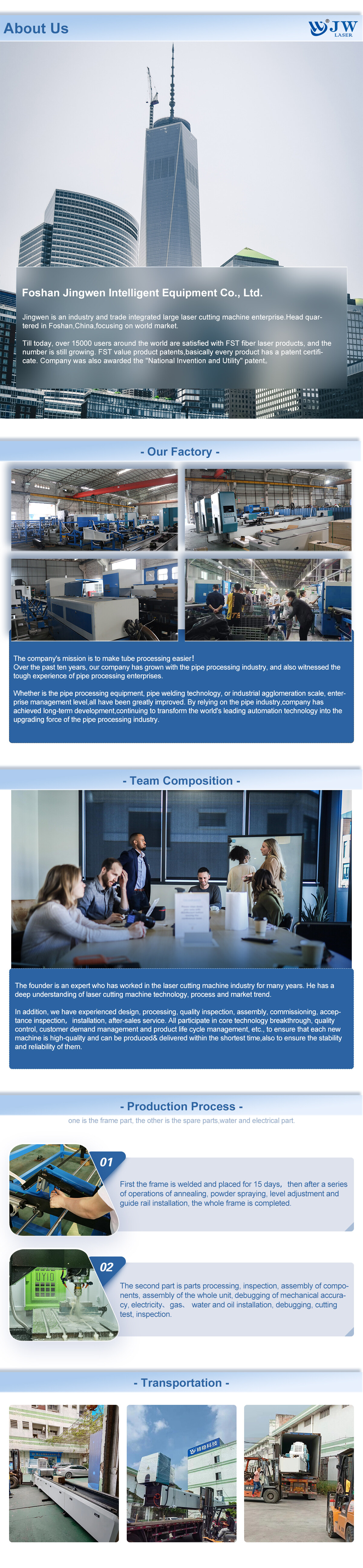

Our independently invented a carbon steel round tube laser cutting machine that can quickly and accurately cut round tubes, rectangular tubes, specialty-shaped tubes, and other profiles. The brand-new metal pipe laser processing production line achieves multi-dimensional cutting in addition to completely automatic production, breaking past the plane cutting restriction. For laser cutting metal pipes, it is the ideal option!

C90D carbon steel round pipe laser cutting machine

Metal pipes are widely used in fitness equipment, construction machinery, home manufacturing, and other industries. In different application scenarios, the shapes of pipes are various, which puts forward higher requirements for the cutting process of metal pipes.

Compared with the traditional cutting process, laser cutting is flexible and does not require mold opening, which greatly saves new product development time, fast cutting speed, and high precision, and the pipe laser cutting machine can realize hole opening, cutting, intersecting lines and conventional methods that are difficult to achieve Precision cutting of various special-shaped complex graphics.

The carbon steel round tube laser cutting machine independently developed by our company can perform high-speed and high-quality laser cutting on round tubes, rectangular tubes, special-shaped tubes, and other profiles. The brand-new metal pipe laser processing production line not only realizes fully automatic production, but also breaks through the limitation of plane cutting, and can realize multi-dimensional cutting. It is the best choice for metal pipe laser cutting!

The features of C90D carbon steel round pipe laser cutting machine

The CNC system adopts a special laser control system and an imported non-contact height tracking system, which is sensitive and accurate in response and avoids the change of cutting quality caused by the "fluctuation" of the plate. And professional CAM software is powerful, has stable operation, simple operation, and is easy to learn.

The machine tool adopts a CNC structure, and the fuselage adopts an integral welding structure and undergoes vibration aging treatment, which can eliminate the stress of welding and processing, and has the advantages of good rigidity, high precision, and no deformation.

Covering industries: sheet metal, jewelry, glasses, mechanical equipment, lighting, kitchen and bathroom products, mobile communications, digital products, electronic components, clocks, computer accessories, instruments, and meters, precision instruments, metal molds, auto parts, craft gifts, etc. chemical industry.