Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

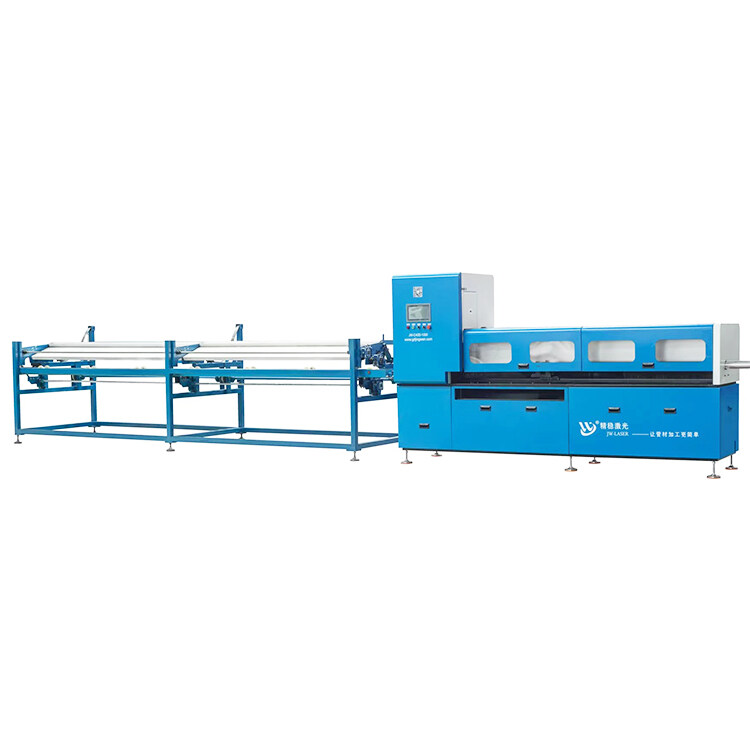

The Ultimate Guide to Bed Frame Laser Pipe Cutting Machines

In the ever-evolving landscape of manufacturing, efficiency and precision are paramount. Enter the bed frame laser pipe cutting machine, a revolutionary tool that has transformed the way bed frames are manufactured. In this comprehensive guide, we delve deep into the intricacies of this cutting-edge technology, exploring its applications, benefits, and everything else you need to know.

Understanding the Bed Frame Laser Pipe Cutting Machine

The bed frame laser pipe cutting machine is a sophisticated piece of equipment designed to streamline the fabrication process of bed frames. By utilizing laser technology, this machine can precisely cut through pipes with unparalleled accuracy, resulting in high-quality components for bed construction.

How Does a Bed Frame Laser Pipe Cutting Machine Work?

At its core, the operation involves the use of a high-powered laser beam directed onto the surface of metal pipes. This laser beam, generated by a resonator, is focused and guided by advanced optical systems to achieve precise cuts. The machine's computerized control system ensures that the cuts are made according to the specified dimensions with minimal deviation.

Applications of Bed Frame Laser Pipe Cutting Machines

The versatility makes them invaluable across various industries. From furniture manufacturing to automotive fabrication, these machines find applications wherever precision cutting of metal pipes is required. Some common applications include:

- Bed Frame Manufacturing: As the name suggests, the cutting machines are extensively used in the production of bed frames. Whether it's standard designs or custom configurations, these machines can accommodate a wide range of specifications.

- Furniture Production: Beyond bed frames, these machines are also utilized in the manufacturing of other furniture pieces that incorporate metal pipe components, such as tables, chairs, and shelving units.

- Automotive Industry: In the automotive sector, the cutting machines play a crucial role in fabricating components for vehicle chassis, exhaust systems, and structural elements.

Advantages of Utilizing Bed Frame Laser Pipe Cutting Machines

The adoption offers several advantages over traditional cutting methods. These include:

- High Precision: The laser cutting technology employed by these machines enables precise cuts with minimal tolerance, ensuring consistency in the dimensions of the fabricated components.

- Increased Efficiency: Compared to conventional cutting techniques, the cutting machines operate at higher speeds, resulting in faster production cycles and increased throughput.

- Reduced Material Waste: The focused nature of laser cutting minimizes material waste by optimizing the use of raw materials, thereby contributing to cost savings and sustainability efforts.

Precision and Accuracy: The Hallmarks of Bed Frame Laser Pipe Cutting Machines

One of the standout features is their ability to achieve exceptional levels of precision and accuracy. This precision is attributed to several factors, including:

- Advanced Laser Technology: The cutting machines utilize state-of-the-art laser systems capable of producing focused beams with diameters as small as a few micrometers, ensuring precise cuts even on intricate patterns.

- Computerized Control Systems: The cutting process is guided by computerized control systems that execute the cutting paths with utmost accuracy, based on the input CAD/CAM designs.

- Dynamic Beam Control: Some advanced models incorporate dynamic beam control features, allowing for real-time adjustments to compensate for factors such as material inconsistencies and thermal effects, further enhancing the precision of the cuts.

Efficiency and Cost Savings: Maximizing Production Output

In today's competitive manufacturing landscape, efficiency is a key determinant of success. The cutting machines offer significant efficiency gains over traditional cutting methods, leading to tangible cost savings and enhanced productivity. Here's how:

- Faster Processing Speeds: The high-powered laser beams used in the cutting machines can cut through metal pipes at speeds several times faster than conventional cutting tools, reducing overall processing times and increasing throughput.

- Minimal Setup Time: Unlike traditional cutting methods that may require extensive setup and tooling changes, the cutting machines can quickly switch between different cutting tasks with minimal downtime, maximizing machine utilization and reducing idle time.

- Streamlined Workflow: Integration with computer-aided design (CAD) and computer-aided manufacturing (CAM) software allows for seamless translation of design specifications into cutting instructions, eliminating manual errors and streamlining the production workflow.

Flexibility and Customization Options

No two bed frame designs are alike, and with a bed frame laser pipe cutting machine, customization options are virtually limitless. Manufacturers can easily accommodate varying design requirements and customer preferences, thanks to the flexibility offered by this technology. Here's how:

- Versatile Cutting Capabilities: The cutting machines can perform a wide range of cutting tasks, including straight cuts, bevel cuts, miter cuts, and intricate patterns, allowing for the fabrication of complex bed frame designs with ease.

- On-the-Fly Adjustments: Advanced control systems enable operators to make real-time adjustments to cutting parameters such as cutting speed, laser power, and focal length, facilitating rapid prototyping and iterative design changes without the need for tooling modifications.

- Integration with Design Software: Seamless integration with CAD software enables designers to create custom bed frame designs with precision and ease, taking full advantage of the machine's capabilities to realize their creative vision.

Sustainability: Redefining Manufacturing Practices

In an era where sustainability is a top priority for many industries, the cutting machines are leading the charge towards eco-friendly manufacturing practices. By minimizing material waste and energy consumption, these machines help reduce the environmental footprint of the manufacturing process. Here's how:

- Material Optimization: The precise nature of laser cutting minimizes material waste by maximizing the utilization of raw materials, reducing scrap and offcuts typically associated with traditional cutting methods.

- Energy Efficiency: Compared to conventional cutting techniques that may rely on mechanical force or thermal processes, laser cutting is inherently more energy-efficient, requiring less power to achieve the same cutting results.

- Reduced Emissions: Laser cutting produces minimal airborne pollutants, as it does not involve the combustion of materials or the use of lubricants and cooling fluids, contributing to cleaner air quality and safer working environments.

Integrating Bed Frame Laser Pipe Cutting Machines Into Your Workflow

Ready to incorporate bed frame laser pipe cutting machines into your manufacturing process? Here's a step-by-step guide to seamlessly integrate this cutting-edge technology into your workflow:

1. Assess Your Requirements: Evaluate your production needs, including the types of bed frames you manufacture, expected production volumes, and desired cutting capabilities.

2. Select the Right Machine: Choose a cutting machine that aligns with your requirements in terms of cutting capacity, precision, and flexibility. Consider factors such as laser power, cutting area size, and automation features.

3. Installation and Setup: Ensure proper installation and calibration of the machine in your facility, following manufacturer guidelines and safety protocols. Train operators on machine operation and maintenance procedures.

4. Integration with CAD/CAM Software: Integrate the cutting machine with your existing CAD/CAM software environment to streamline design-to-production workflows and facilitate data exchange between design and manufacturing teams.

5. Optimize Cutting Parameters: Fine-tune cutting parameters such as laser power, cutting speed, and assist gas pressure to achieve optimal cutting results for different materials and thicknesses.

6. Quality Assurance and Testing: Implement quality assurance measures to verify the accuracy and consistency of the cut components, conducting test runs and inspections to ensure compliance with design specifications.

7. Continuous Improvement: Regularly monitor machine performance and production output, seeking opportunities for optimization and efficiency gains through process refinement and technology upgrades.

Future Trends and Innovations in Bed Frame Laser Pipe Cutting Technology

As technology continues to advance at a rapid pace, what does the future hold for bed frame laser pipe cutting machines? Explore upcoming trends and innovations that promise to further revolutionize the manufacturing landscape:

- Enhanced Automation: Continued advancements in robotics and artificial intelligence are expected to enable greater automation of the cutting process, reducing the need for manual intervention and increasing production efficiency.

- Multi-Material Cutting: Future iterations of the cutting machines may incorporate capabilities for cutting a wider range of materials beyond metals, including composites, plastics, and ceramics, expanding their applicability across diverse industries.

- Integration with Additive Manufacturing: The integration of laser cutting technology with additive manufacturing processes such as 3D printing holds the potential to create hybrid manufacturing systems capable of producing complex, multi-material components with unprecedented precision and efficiency.

- Augmented Reality (AR) Interfaces: AR-based user interfaces may enhance operator productivity and ease of use by providing real-time visual feedback and guidance during machine setup, operation, and maintenance tasks.

Conclusion: Embracing the Future of Manufacturing

In conclusion, bed frame laser pipe cutting machines represent the pinnacle of precision, efficiency, and sustainability in manufacturing. By harnessing the power of laser technology, manufacturers can elevate their production processes to unprecedented heights, achieving levels of precision and customization that were previously unattainable.