Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

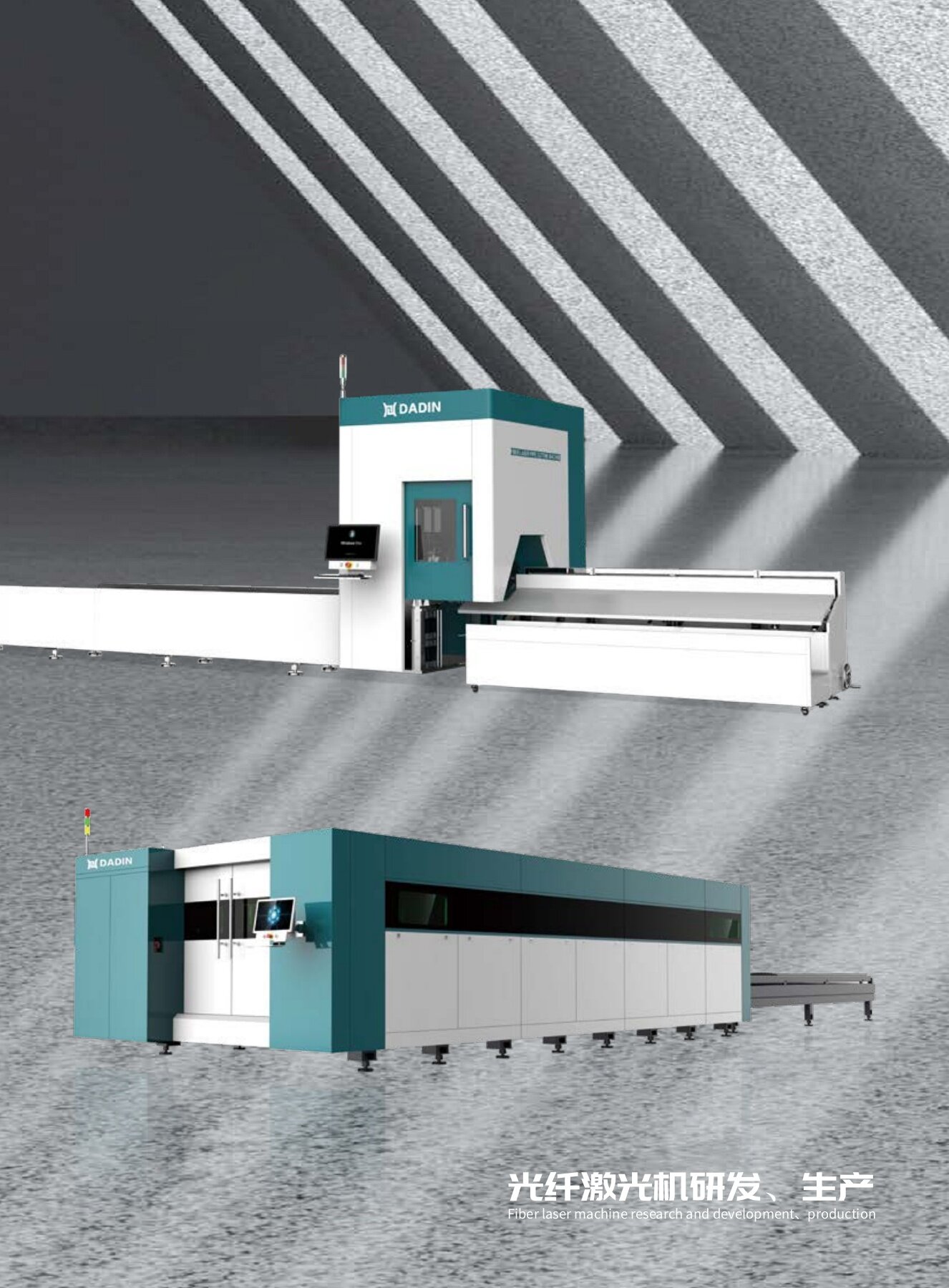

Unleashing Precision and Versatility: Exploring Metal Tube and Plate Fiber Laser Cutting Machines

In the dynamic landscape of metal fabrication, the demand for precision, efficiency, and versatility continues to drive innovation. Among the cutting-edge technologies revolutionizing manufacturing processes, metal tube and plate fiber laser cutting machines stand out as indispensable tools for businesses seeking to stay ahead of the curve. In this comprehensive guide, we will delve into the intricacies of these cutting-edge machines, exploring their capabilities, applications, and the key factors driving their adoption in the manufacturing sector.

Understanding Metal Tube and Plate Fiber Laser Cutting Machines

The laser cutting machines represent a pinnacle of cutting technology, combining the versatility of fiber lasers with the capability to process both flat and cylindrical metal components. Unlike traditional cutting methods such as sawing or milling, which can be time-consuming and imprecise, fiber laser cutting machines harness the power of focused laser beams to achieve clean, precise cuts across a wide range of metal materials.

The heart of these machines lies in their fiber laser sources, which generate intense beams of light capable of cutting through metal with remarkable accuracy. These lasers are guided by sophisticated motion control systems, allowing for precise positioning and movement of the cutting head along the material surface. Whether cutting thin sheets of metal or thick-walled tubes, the cutting machines deliver clean edges, sharp corners, and precise dimensions, ensuring superior quality and consistency in the finished products.

The Advantages of Metal Tube and Plate Fiber Laser Cutting Machines

1. Precision Engineering: The cutting machines offer unmatched precision, enabling manufacturers to achieve intricate cuts with micron-level accuracy. Whether cutting thin sheets of metal or thick-walled tubes, these machines deliver clean edges, sharp corners, and precise dimensions, ensuring superior quality and consistency in the finished products.

2. Versatility: One of the key advantages is their versatility. Unlike traditional cutting methods that may require multiple machines for processing different types of materials, fiber lasers can effortlessly handle a wide range of metals, including stainless steel, aluminum, brass, and copper, as well as non-metal materials like plastics and composites. This versatility makes them invaluable assets for manufacturers operating in diverse industries, from automotive and aerospace to electronics and furniture.

3. High-Speed Performance: In addition to precision and versatility, the cutting machines excel in speed, enabling rapid processing of metal components with minimal downtime. With their high-powered laser sources and advanced motion control systems, these machines can achieve cutting speeds that far surpass traditional methods, allowing manufacturers to meet tight production deadlines and maximize throughput.

Applications of Metal Tube and Plate Fiber Laser Cutting Machines

Metal tube and plate fiber laser cutting machines find applications across a wide range of industries and manufacturing processes. Some common applications include:

1. Sheet Metal Fabrication: The cutting machines are widely used in sheet metal fabrication for cutting flat metal sheets into various shapes and sizes. From automotive body panels to precision components for electronics, fiber lasers offer unmatched accuracy and efficiency in processing sheet metal materials.

2. Tube and Pipe Cutting: In addition to flat sheets, the cutting machines are also capable of cutting cylindrical metal components such as tubes and pipes. This capability is particularly valuable in industries such as construction, furniture manufacturing, and automotive, where tubular components are prevalent.

3. Structural Steel Processing: Fiber lasers are increasingly being used for cutting structural steel components such as beams, channels, and angles. Their ability to deliver precise cuts with minimal heat-affected zones makes them ideal for fabricating structural components with tight tolerances and complex geometries.

Key Considerations When Choosing a Metal Tube and Plate Fiber Laser Cutting Machine

When investing in a metal tube and plate fiber laser cutting machine, several key factors should be considered to ensure optimal performance and return on investment:

1. Laser Power and Source: The laser power and source type (fiber laser or CO2 laser) play a crucial role in determining the cutting capabilities and performance of the machine. Higher laser power allows for faster cutting speeds and increased productivity, while the choice between fiber and CO2 lasers depends on factors such as material type, thickness, and desired cutting quality.

2. Machine Size and Configuration: The size and configuration of the machine should be chosen based on the specific application requirements, including the size and thickness of the materials to be cut, as well as production volume and space constraints.

3. Automation and Integration: Advanced features such as automatic material handling, nozzle changing systems, and integrated CAD/CAM software can significantly enhance the efficiency and productivity. Consideration should be given to the level of automation and integration needed to streamline production workflows and minimize manual intervention.

4. Support and Service: Selecting a reputable manufacturer with a track record of providing excellent support and service is essential to ensure the long-term reliability and performance of the machine. Look for manufacturers that offer comprehensive training programs, responsive technical support, and timely maintenance services to keep your machine running smoothly.

Conclusion

Metal tube and plate fiber laser cutting machines represent a transformative technology that offers unparalleled precision, versatility, and efficiency in metal fabrication. With their ability to process both flat and cylindrical metal components with exceptional accuracy and speed, these machines are revolutionizing manufacturing processes across a wide range of industries. By understanding their capabilities, applications, and key considerations when choosing a machine, businesses can unlock new opportunities for innovation and growth in metal fabrication.