Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

China laser plate tube cutter machine factories

As the demand for precision cutting in various industries continues to grow, laser plate tube cutter machines have become increasingly popular. These machines use a high-powered laser beam to cut through metal plates and tubes, offering precision and speed that traditional cutting methods cannot match. Jingwen is one of the leading China laser plate tube cutter machine factories, having produced and exported many high-quality machines around the world.

How laser plate tube cutter machines work

Laser plate tube cutter machines use a process called laser cutting, which involves directing a high-powered laser beam at a metal material to be cut. The laser beam melts or vaporizes the material, allowing it to be cut with a high degree of precision. These machines are equipped with a computer numerical control (CNC) system, which allows for precise control over the cutting process.

There are different types of laser plate tube cutter machines, including CO2 lasers, fiber lasers, and hybrid lasers. CO2 lasers use a gas mixture to generate the laser beam, while fiber lasers use a fiber optic cable to amplify the laser light. Hybrid lasers combine the benefits of both CO2 and fiber lasers, offering a versatile cutting option.

Advantages of China-made laser plate tube cutter machines

China-made laser plate tube cutter machines offer several advantages over machines produced in other countries, including:

Affordability: China-made machines are often more affordable than machines produced in other countries, making them a popular choice for small to medium-sized businesses.

Quality: China has made significant strides in improving the quality of its laser plate tube cutter machines, with many factories producing high-quality machines that meet international standards.

Customization: Many China-made machines can be customized to meet specific cutting requirements, allowing for greater flexibility in the cutting process.

Technical support: Many China-based manufacturers offer technical support and after-sales service, helping businesses get the most out of their machines.

Jingwen is a China leading factory of laser plate tube cutter machines, producing high-quality machines that are affordable and customizable. Jingwen machines offer many advantages that make them a popular choice for businesses across various industries. As technology continues to advance, we can expect to see even more innovative laser plate tube cutter machines coming from Jingwen.

C220DX aluminum pipe CNC 3D laser cutting machine

The laser three-dimensional pipe-cutting machine's ability to advance so quickly in a short amount of time is due to its flexibility in processing a variety of components, high precision in meeting the needs of the majority of customers for high-precision components, and lack of artificial assistance. Its highlights now include the benefits of intervention operations, quick processing times, and cost savings.

C250D stainless steel round pipe laser cutting machine

A specialized machine tool known as a round tube laser cutting machine employs laser technology to carve different graphics on pipe fittings and profiles. It is a high-tech product that combines laser cutting, numerical control technology, and precise equipment. It is the equipment of choice for the non-contact metal pipe processing business due to its professionalism, high speed, high precision, high efficiency, and high cost performance. It won't apply any pressure to the pipe wall at any point during the processing, thus the pipe's outer surface won't deform or collapse.

C120D stainless steel round pipe laser cutting machine

With their high speed, high efficiency, and high quality, pipe laser cutting machines have increasingly taken the position of conventional flame cutting, plasma cutting, water cutting, and other traditional processing equipment to become the primary instrument for metal processing. These qualities also facilitate more demanding and complicated metal processing, enabling designers' whims to come to life in their drawings.

C120X stainless steel pipe high precision laser cutting machine

Metal is typically cut using high-precision laser cutting devices. When cutting metal materials with a diameter of 1mm, the laser cutting machine's diameter of the laser beam can reach about 0.2mm, and the cutting pattern is extremely accurate. This not only enhances the technical content and artistic taste of sheet metal processing, but also raises the profit margin. As a result, in order to improve the performance of the machinery, we must value and standardize the operation of high-precision laser cutting machines.

High speed aluminum pipe CNC 3D laser cutting machine C130DX

A high-tech product merging numerical control technology, laser cutting, and precision machinery is the CNC three-dimensional laser pipe cutting machine. It is mostly used for metal pipes, such as square, round, OB, and profile pipes made of carbon steel, stainless steel, and aluminum alloy. It performs with professionalism, high efficiency, and high cost. It is the industry standard for non-contact metal pipe processing.

C150D aluminum round pipe laser cutting machine

A high-end tool for precisely cutting pipe materials is the round pipe laser pipe cutter. A laser, a gantry, a machine tool, a round pipe fixture, a numerical control panel, and a cooler are the typical components. In addition to cutting round pipes, the round pipe laser pipe cutting machine can also bevel cut various materials like square and flat pipes as well as cut, punch, hollow out, and engrave the pipe wall.

C120X aluminum pipe high precision laser cutting machine

For cutting unique profiles, a high-precision laser pipe cutting machine is appropriate. Moreover, it has an autonomous material-pushing system to cut down on cutting expenses and produce "zero tailings." It is widely employed in a variety of industries, including sports equipment, chemical equipment, and pipelines for oil. can cut aluminum, stainless steel, and carbon steel.

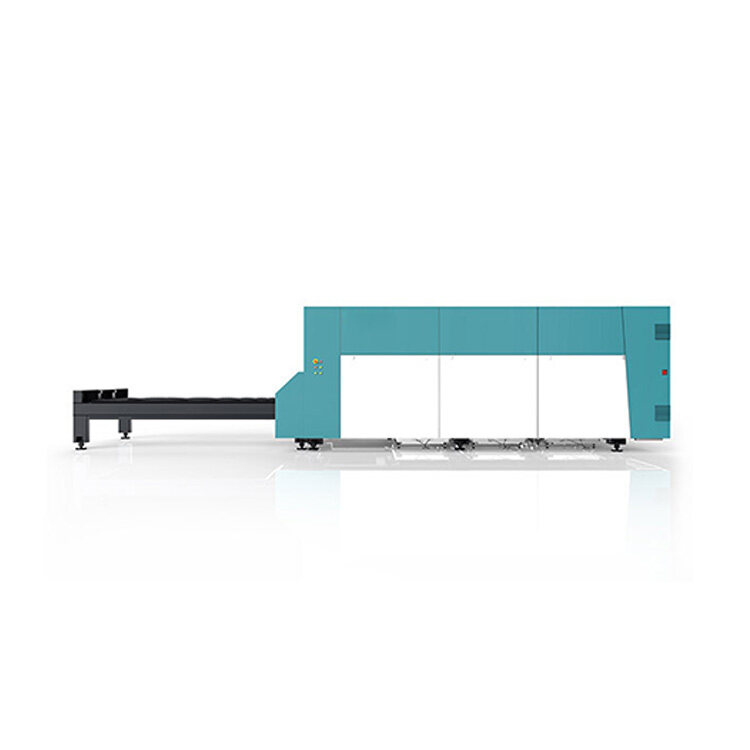

DF-3015X Metal Sheet Laser Cutting Machine

Our DF-3015X Metal Sheet Laser Cutting Machine uses an imported servo motor that offers excellent performance, high speed, stability, and durability, ensuring the machine's overall high speed and acceleration.