Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Automation Equipment

Automation Equipment

(2)Jingwen is a company that provides automation equipment around laser cutting machines. Our company aims to enhance productivity and efficiency in the manufacturing industry by automating the process of loading and unloading materials in laser cutting machines. We provide a range of automation equipment, including semi-automatic loading racks, fully automatic loading racks, and slag extractors. Our equipment is designed to improve the speed and accuracy of the laser cutting process while reducing labor costs and increasing production output.

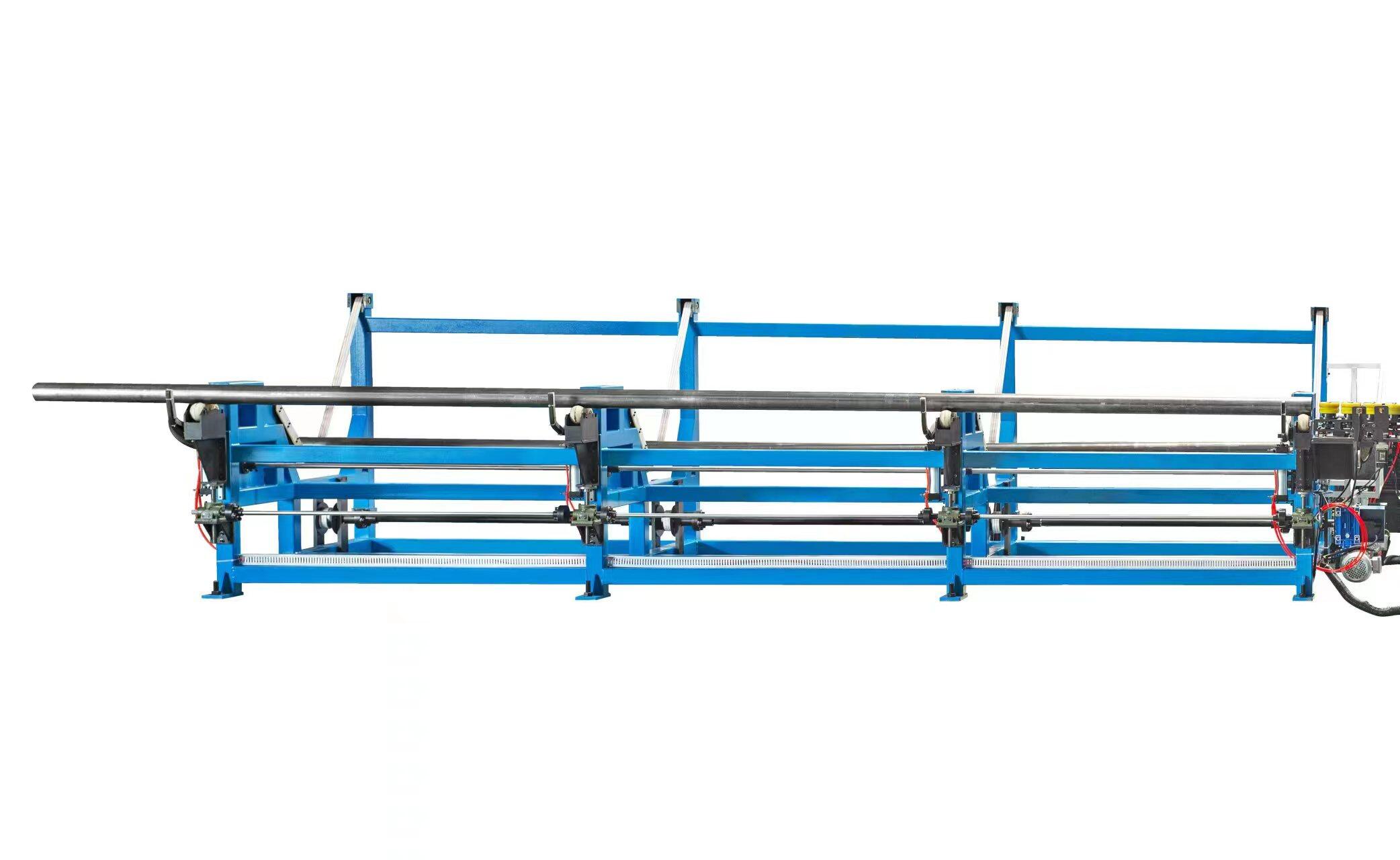

Fully automatic loading rack:

Our fully automatic loading rack takes automation to the next level. The fully automatic loading rack consists of a conveyor system that moves materials from a storage area to the laser cutting machine. The materials are then automatically loaded onto the laser cutting bed, and the cutting process begins. Once the cutting process is complete, the finished materials are automatically unloaded onto an unloading rack.

The fully automatic loading rack is designed to provide maximum automation, minimizing the need for manual labor. The conveyor system is programmed to move materials from storage to the laser cutting machine, reducing the need for operators to move materials manually. Additionally, the fully automatic loading rack is designed to work seamlessly with our slag extractor, which further reduces the need for manual labor in the laser cutting process.

One of the significant benefits of the fully automatic loading rack is that it can significantly increase productivity. With the conveyor system and automated loading and unloading, materials can be loaded and unloaded quickly and accurately, reducing downtime and increasing production output. Additionally, the fully automatic loading rack can be customized to fit a wide range of materials, making it a versatile option for manufacturing facilities.

Semi-automatic loading rack:

Our semi-automatic loading rack is designed to streamline the process of loading and unloading materials in laser cutting machines. The semi-automatic loading rack consists of a robotic arm that picks up the material and places it onto the laser cutting bed. The operator then manually positions the material to ensure it is in the correct location for cutting. Once the cutting process is complete, the robotic arm picks up the finished material and places it onto an unloading rack.

One of the significant benefits of the semi-automatic loading rack is that it reduces the need for manual labor. With the semi-automatic loading rack, the operator only needs to position the material, reducing the physical effort required to move materials into the laser cutting machine. This not only reduces labor costs but also minimizes the risk of injuries associated with manual material handling.

The semi-automatic loading rack also increases efficiency by reducing the time it takes to load and unload materials into the laser cutting machine. With the semi-automatic loading rack, the robotic arm can move materials quickly and accurately, reducing downtime and increasing productivity. Additionally, the semi-automatic loading rack can be customized to fit a wide range of materials and can be integrated with existing laser cutting machines.

Slag extractor:

Our slag extractor is designed to automate the process of removing slag from laser-cut materials. Slag is a byproduct of the laser cutting process that can accumulate on the surface of the material, reducing the quality of the finished product. The slag extractor is designed to remove this slag automatically, reducing the need for manual labor and improving the quality of the finished product.

The slag extractor consists of a vacuum system that sucks the slag off the surface of the material. The vacuum system is mounted on a robotic arm that moves over the material, removing the slag from the surface. Once the slag is removed, the finished product is ready for the next stage of production.

Overall, Jingwen's automation equipment is designed to streamline the laser cutting process, reduce labor costs, and improve the quality and consistency of the finished product. With their commitment to quality and innovation, Jingwen is a trusted partner for businesses looking to maximize the efficiency of their laser cutting operations.

Fully automatic loading rack

A newly created feeding rack for supporting the laser cutting machine is the fully automatic loading rack. It has high efficiency, consistent feeding, and complete automatic control.

Semi-automatic loading rack

The one-button semi-automatic loading rack is simple to use and can increase work productivity. However, when changing the kind of tube, you must manually adjust the size restriction of the tube loading. The equipment is light and has a small footprint, so it can be transported and docked with ease. The structure is straightforward, which can account for the stability of the equipment.