Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

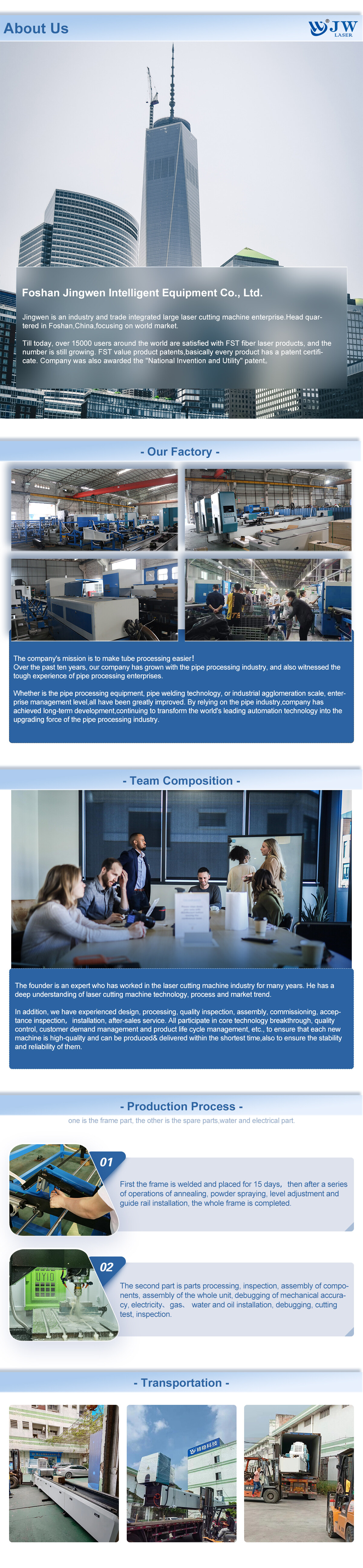

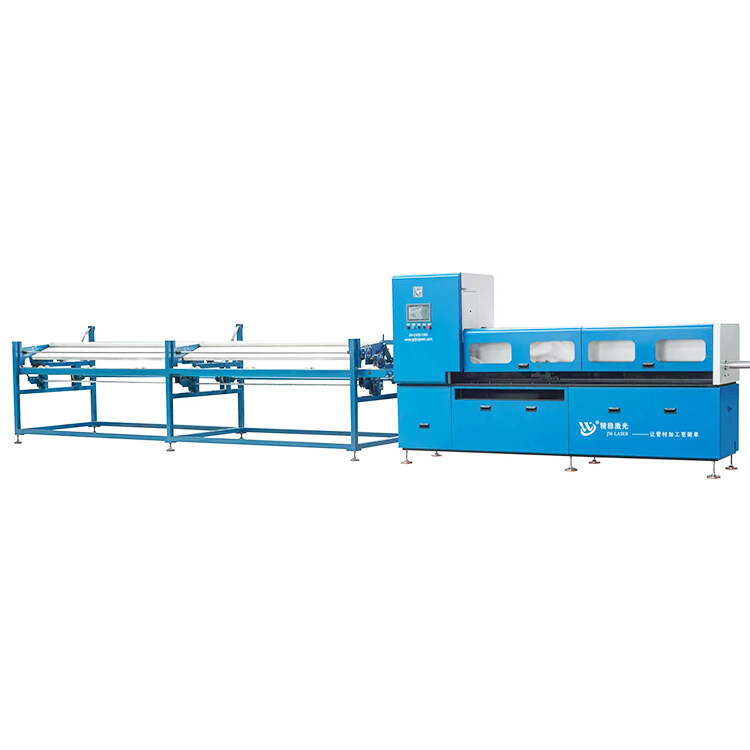

C120D aluminum round pipe laser cutting machine

A variety of aluminum round tubes in various shapes can be cut with the aluminum round tube laser cutting equipment. The cutting tube measures 6.2 meters in length and has an 8mm wall thickness. The workpiece has excellent precision after cutting it out, thus further processing is not necessary. You can do high-quality, high-output work since the cutting is faster and more stable.

C120D aluminum round pipe laser cutting machine

The aluminum round tube laser cutting machine is suitable for cutting a variety of aluminum round tubes in different shapes. The length of the cutting tube is 6.2 meters, and the thickness of the tube wall is 8mm. After cutting out, the workpiece has high precision and does not need secondary processing. The cutting is more stable and the speed is faster, allowing you to produce high-quality and high output.

The advantages of C120D aluminum round pipe laser cutting machine

The high automation and high precision of the round tube laser cutting machine can save labor costs, drill bits, saw blades, and other consumable costs for the enterprise. The processing efficiency is high, and the cost can be paid back quickly, and the economic benefits are very high. Therefore, in the long run, it not only has high efficiency, low cost, and the quality of processed pipe fittings cannot be achieved by traditional machinery, but also can realize a variety of processes, and one machine with multiple functions has become an ideal equipment for round pipe cutting today.

The features of C120D aluminum round pipe laser cutting machine

- There are many types of cutting pipes, and they can cut, punch, hollow out, and engrave pipe walls, bevel cutting, and other three-dimensional processing of round pipes, square pipes, flat pipes, and other materials.

- The laser processing speed is fast and the cutting precision is high, which can realize high-efficiency processing in large quantities.

- The laser cutting machine series equipment is easy to operate; adopts the numerical control operation platform, inputs the corresponding drawings, and realizes fast processing, flexible and fast.

The working principle of C120D aluminum round pipe laser cutting machine

Through the cooperation of computer and hydraulic pressure, the electric system controls the oil circuit movement direction of the hydraulic system and pushes the carriage back and forth in a straight line. The microcomputer will walk according to the user-edited cutting route. During the reciprocating movement, the signal detected by the carriage limit is used as a basis to control and change the movement of its oil circuit, to achieve the expected cutting route.