Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

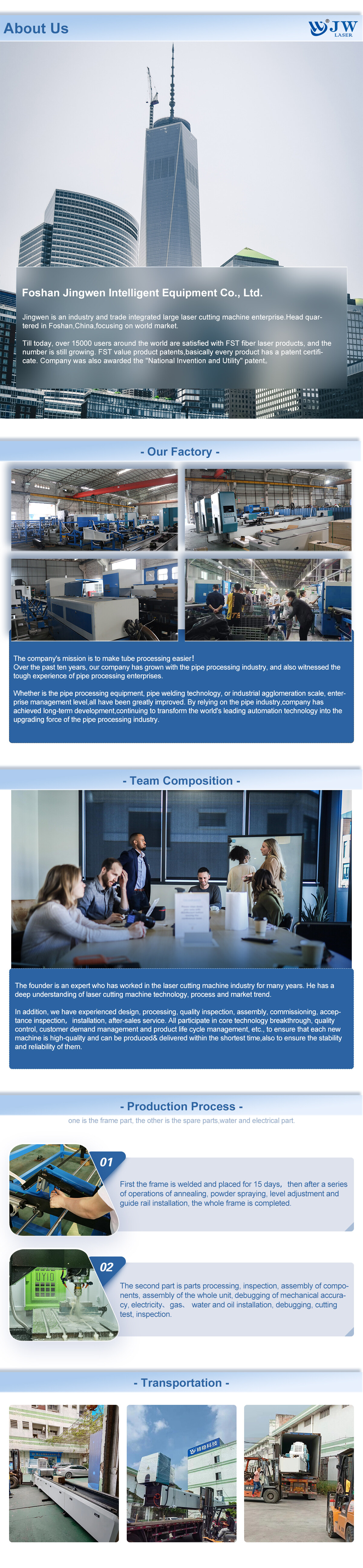

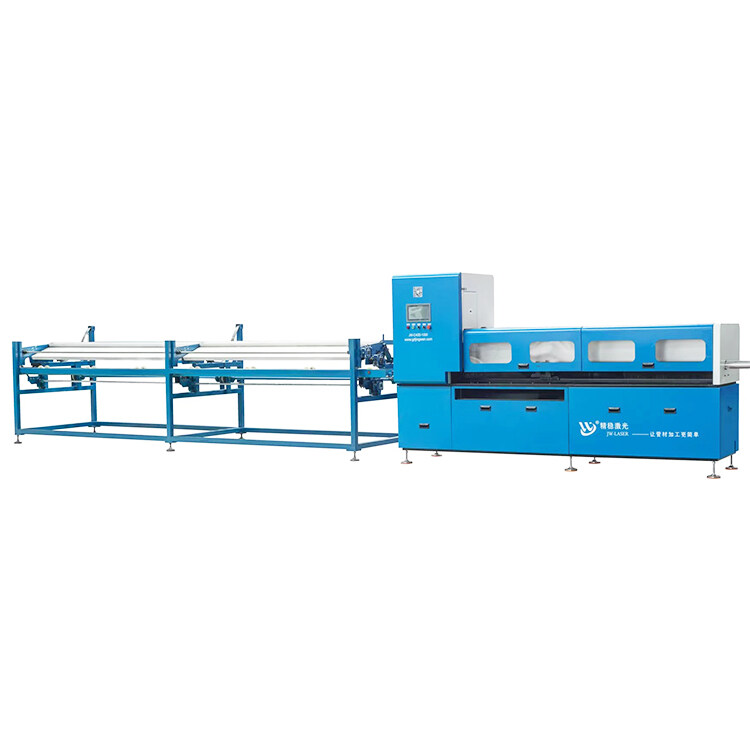

C200D aluminum round pipe laser cutting machine

Several industries employ the round tube laser cutting machine, which significantly decreases processing time, lowers processing costs, and raises the caliber of the finished product. Handicrafts, electronics, toys, sheet metal, hardware, jewelry, nameplates, ads, packaging, steel constructions, precision machinery, car parts, glass, and other sectors are among those involved. Stainless steel plates, iron plates, aluminum materials, ceramic sheets, silicon sheets, diamonds, etc. are typical materials used for laser cutting.

C200D aluminum round pipe laser cutting machine

The round tube laser cutting machine has a wide range of uses in many fields, which greatly reduces the processing time, reduces the processing cost, and improves the quality of the workpiece. The industries involved include handicrafts, electronics, toys, sheet metal, hardware products, jewelry, nameplates, advertisements, packaging steel structures, precision machinery, auto parts, glasse,s and other industries. Laser cutting products usually include stainless steel plates, iron plates, aluminum materials, ceramic sheets, silicon sheets, diamonds, etc.

The working principle of C200D aluminum round pipe laser cutting machine

The circular tube laser cutting machine uses the energy released when the laser beam irradiates the surface of the workpiece to melt and evaporate the workpiece to achieve the purpose of cutting and engraving. No need for mold opening and tools, no stress on the product, high precision, fast cutting, not limited to cutting pattern restrictions, automatic typesetting saves materials, smooth cuts, and low processing costs.

The maintenance of C200D aluminum round pipe laser cutting machine

Lens cleaning

There are 3 reflecting mirrors and 1 focusing mirror on the laser cutting machine, the laser is reflected and focused by these mirrors and emitted from the laser head. The lens is easily stained with dust or other pollutants, which will cause loss of laser light or damage to the lens. No. 1 and 2 lenses do not need to be removed when cleaning, just carefully wipe the lens with the lens cleaning paper dipped in cleaning fluid along the center of the lens. Edge swivel wipe. The No. 3 lens and focusing lens need to be taken out of the frame, wiped in the same way, and then put back in the same way after wiping.

Fan cleaning

Long-term use of the fan will cause a lot of solid dust to accumulate in the fan, making the fan produce a lot of noise, which is not conducive to exhaust and deodorization. When the suction of the fan is insufficient and the smoke exhaust is not smooth, first turn off the power, remove the air inlet and outlet pipes on the fan, remove the dust inside, then turn the fan upside down, and pull the blades inside until it is clean, and then install the fan.