Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

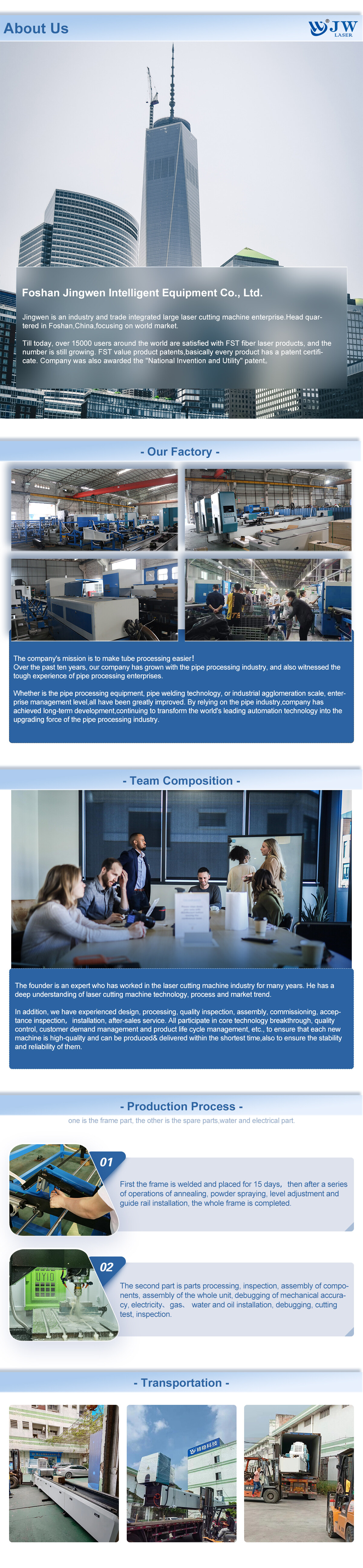

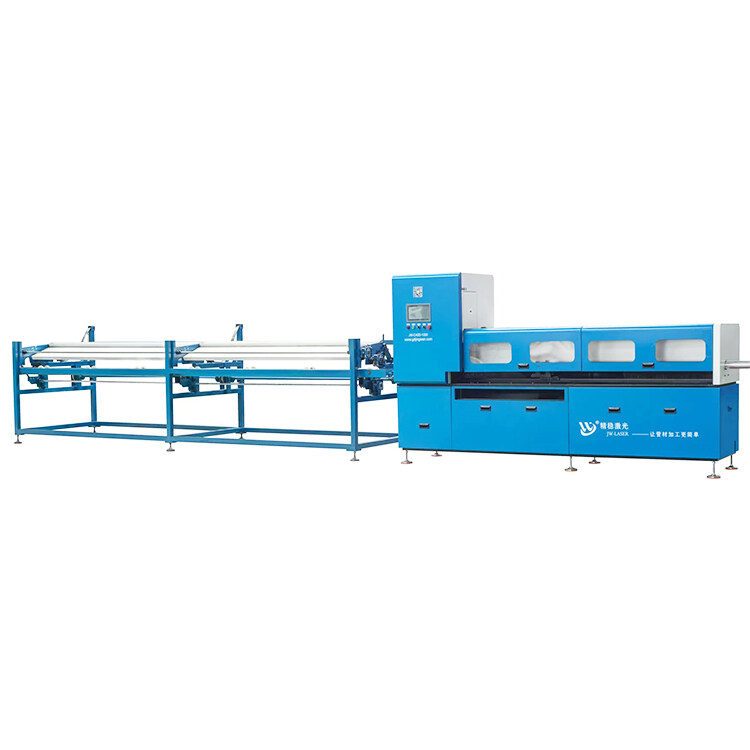

C40D stainless steel round pipe laser cutting machine

The stainless steel round tube laser cutting machine uses a large processing area and two heads that move together when cutting the laser. The left and right feeding and receiving devices on the negative pressure crawler-type working platform enable simultaneous discharging, cutting, and receiving of materials, considerably reducing the time between processes. Time increases processing output and work efficiency.

C40D stainless steel round pipe laser cutting machine

The stainless steel round tube laser cutting machine adopts two-head mutual-moving laser cutting, and the processing area is large. The negative pressure crawler-type working platform is equipped with left and right feeding and receiving devices so that discharging, cutting, and receiving materials can be completed in one go, which greatly reduces the time between processes. Time improves work efficiency and processing output.

The Advantages of C40D stainless steel round pipe laser cutting machine

- High cutting precision: The stainless steel round tube laser cutting machine adopts a modular design, and the servo system precisely controls the cutting size;

- Dedicated to a special purpose; the stainless steel round tube laser cutting machine is only for cutting round tubes. The chuck has high precision and is suitable for cutting small-diameter round tubes. The cutting diameter range is 6mm-42mm (the cutting range can be customized not exceeding 76mm diameter round tube), Cutting length is 20mm-1200mm adjustable;

- High cutting efficiency; the stainless steel round tube laser cutting machine has no cumbersome processing technology, and there are two styles of manual feeding and automatic feeding to choose from. In the case of cutting long materials, manual loading, and unloading is convenient and fast, which is faster than mechanical automatic loading and unloading;

- The operation is simple, the structure of the stainless steel laser tube cutting machine is simple and practical, and there is no need for too many adjustments to change the specifications. The stainless steel round tube laser cutting machine with manual feeding can be operated by a single person; the automatic stainless steel round tube laser cutting machine with automatic feeding system Fully automated production can be realized, and the operation is simpler!

FAQ

Q: How about a guarantee?

A: The machine's main parts (excluding consumables) will be replaced without charge (some parts will be maintained) if there is an issue during the warranty period.