Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

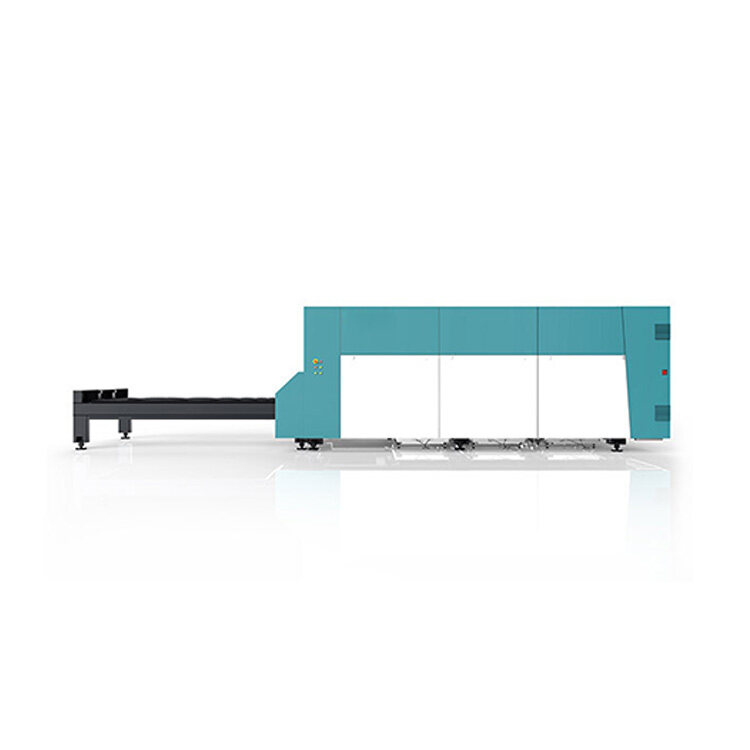

DF-3015X Sheet Metal Laser Cutting Machine

DF-3015X Sheet Metal Laser Cutting Machine

(1)Sheet metal laser cutting machines are powerful tools that have revolutionized the metalworking industry. They offer numerous advantages over traditional cutting methods, such as shearing, punching, and sawing.

Precision

Sheet metal laser cutting machines are incredibly precise. They use a focused beam of light to cut through the material, which ensures a high level of accuracy. The laser beam is so thin that it can cut through the material without damaging it, resulting in clean and precise cuts. This level of precision is impossible to achieve with traditional cutting methods, making laser cutting machines ideal for complex and intricate designs.

Speed

Sheet metal laser cutting machines are also incredibly fast. They can cut through the material at a much faster rate than traditional cutting methods. This is because the laser beam can move quickly and efficiently through the material, resulting in faster production times. This speed is particularly important in industries where time is of the essence, such as automotive and aerospace.

Versatility

Sheet metal laser cutting machines are incredibly versatile. They can cut through a wide range of materials, including steel, aluminum, brass, copper, and titanium. This versatility means that businesses can use the same machine for multiple projects, which can save both time and money. Additionally, laser cutting machines can cut through materials of varying thicknesses, making them ideal for a wide range of applications.

Consistency

Sheet metal laser cutting machines offer a high level of consistency. This is because the laser beam is controlled by a computer, which ensures that the cuts are consistent from one piece to the next. This level of consistency is important in industries where precision and quality are paramount, such as medical and aerospace.

Efficiency

Sheet metal laser cutting machines are incredibly efficient. They use a minimal amount of energy to cut through the material, which results in lower energy costs. Additionally, laser cutting machines produce less waste than traditional cutting methods, which can save businesses money on material costs. This efficiency is important in industries where cost-saving measures are crucial, such as manufacturing.

Safety

Sheet metal laser cutting machines are also incredibly safe. They use a non-contact cutting method, which means that the operator is not exposed to the cutting process. Additionally, laser cutting machines are equipped with safety features, such as automatic shut-off systems, which help prevent accidents. This level of safety is important in industries where employee safety is a top priority, such as manufacturing and aerospace.

Automation

Sheet metal laser cutting machines can be fully automated. This means that businesses can program the machine to cut a specific design or pattern, and the machine will do the rest. This automation can save businesses time and money, as it eliminates the need for manual labor. Additionally, automation can improve the accuracy and consistency of the cuts, which can improve overall product quality.

In conclusion, sheet metal laser cutting machines offer numerous advantages over traditional cutting methods. They are incredibly precise, fast, versatile, consistent, efficient, safe, and can be fully automated. These advantages make laser cutting machines ideal for a wide range of industries, including manufacturing, automotive, aerospace, and medical. If you're in the market for a new cutting machine, consider investing in Jingwen sheet metal laser cutting machine to take your business to the next level.

DF-3015X Metal Sheet Laser Cutting Machine

Our DF-3015X Metal Sheet Laser Cutting Machine uses an imported servo motor that offers excellent performance, high speed, stability, and durability, ensuring the machine's overall high speed and acceleration.