Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Machine Components

Machine Components

(12)Jingwen is a company that provides a wide range of professional laser cutting machines and related parts for the cutting machines industry. They offer a comprehensive selection of equipment and components, including laser heads, laser sources, servo motors and drives, precision reducers, precision helical racks, automatic oil supply systems, standard electrical components, precision rails, cooling systems, pipe welding machine tools, pneumatic double chucks, hollow pneumatic rotary chucks, and centering feeding wheels.

Our equipment and components are designed to meet the needs of a variety of cutting machine applications, from small businesses to large industrial operations. With a focus on precision and efficiency, Jingwen's products are built to deliver high-quality results and reliable performance.

Jingwen is committed to providing exceptional customer service, offering expert technical support and advice to help their customers get the most out of their cutting machines. Whether you're looking to purchase new equipment or need replacement parts for your existing machines, Jingwen is the go-to source for all your laser cutting needs.

Laser head

The main part of a laser cutting machine that controls cutting quality is the laser cutting head. The design of the optical path, the cooling system, and the placement of the motor are just a few of the challenges that the laser cutting head must overcome.

Fiber Laser Source Module

The fiber laser source is a cutting-edge technology that revolutionizes laser applications. With its advanced design and state-of-the-art features, this fiber laser source is the ultimate solution for all your laser needs. Whether you're in the manufacturing industry, medical field, or research sector, this remarkable device will exceed your expectations.

Servo Motor and Drive Package

Servo motors and drives are the heart and soul of motion control systems. They are essential components in a wide range of applications, from robotics and CNC machinery to packaging and automation. These systems are designed to offer precise control of position, speed, and acceleration, making them ideal for tasks that require a high degree of accuracy and efficiency.

Precision Reducer

The high stiffness, high precision (within 1 minute for a single stage), high transmission efficiency (97%-98% for a single stage), high torque/volume ratio, and maintenance-free for life are all features of the precision planetary reducer. The majority of them are mounted on servo and stepper motors to decrease speed, improve torque, and match inertia.

Automatic Oil Supply System

A motor-driven gear pump drives the automated lubricating pump. Incorporating a controller of the "MY" type, an automatic emptying valve, a switch for the liquid level, etc. It is a pump that operates sporadically. For a volumetric quantitative centralized lubrication system that requires routine maintenance. Power up so that it can begin operating automatically. It contains features including an output joint control signal and a liquid level alarm.

Precision Rail

A type of workpiece called a precision rail causes the slider to move back and forth on the guide rail by use of balls or rollers. It has a high positioning accuracy and high stiffness and has a friction coefficient of 1/40 of the conventional hard rail. It is therefore frequently used in CNC machine tools, automation, CNC woodworking machinery, optical fiber cutting machines, drilling machines, 3C electronics, glass edge grinders, advertising printing machines, picture machines, and other industrial equipment.

Cooling System

The laser chiller is a customized use of commercial refrigerators in the laser sector. The laser chiller's primary function is to cool the laser generator of the laser equipment using water circulation, and it also regulates the laser generator's operating temperature to ensure long-term maintenance of the laser generator. ordinary work.

Pipe Welding Machine Tool

The major applications of pipe welding machine tools are the fabrication of carbon and stainless steel pipes for home furnishings, products, and appliances. Round pipes, square pipes, and rectangular pipes can be fashioned out following the molding of this group of elements. Also, it has the ability to create pipes that are elliptical, semicircular, plum blossom-shaped, and other unique shapes. such as electric heating pipes, burglar-proof doors and windows, and stainless steel stair railings.

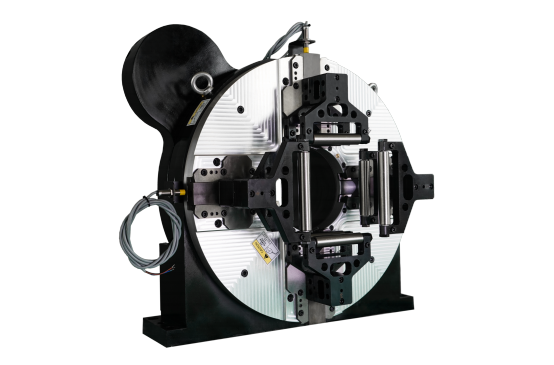

Pneumatic Double Chuck

The uniformly spaced movable jaws on the chuck body of the laser pneumatic chuck move radially to clamp and position the workpiece. The moving jaw, the transmission mechanism for the moving jaw, and the chuck body normally make up the laser pneumatic chuck.

Hollow Pneumatic Rotary Chuck

A tapping chuck called a hollow pneumatic rotary chuck is used on machine machines to clamp taps while internally threaded holes are being processed. Tap chucks, chuck jackets, compression springs, steel balls, and tap jackets make up the majority of its parts.

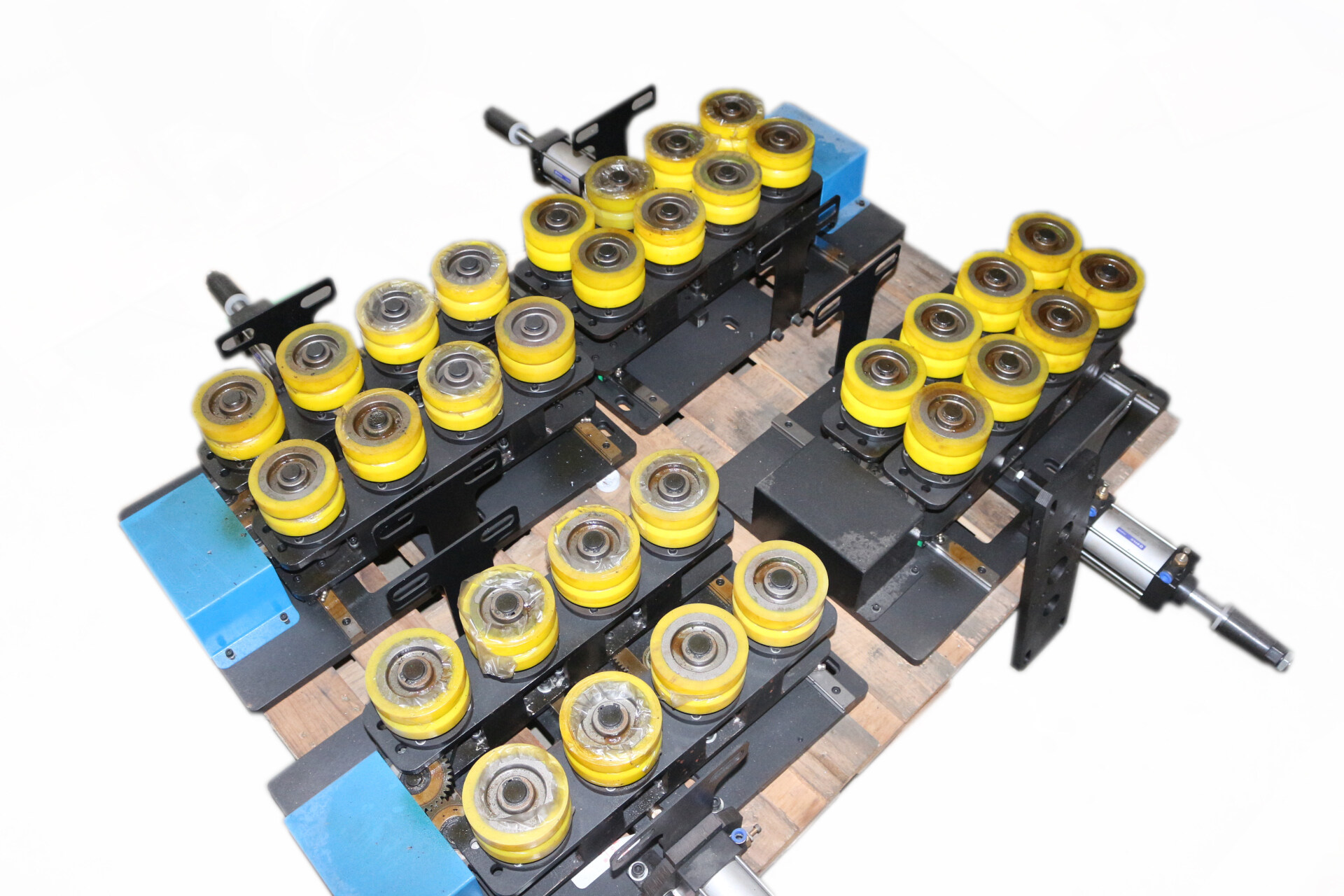

Centering feeding wheel

Introducing the Centering Feeding Wheel, a revolutionary tool designed to enhance precision and efficiency in your manufacturing process. This innovative device ensures accurate alignment and smooth feeding of materials, eliminating errors and reducing downtime. Experience seamless operations and improved productivity with the Centering Feeding Wheel.

Precision Helical Rack

Precision Helical Rack is entirely imported, contains all necessary steel components, and has high wear resistance. The important components of the rack will not be harmed by laser quenching. There won't be any quality issues even if it operates constantly at high speed while under strong strength and heavy load.