Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Metal Sheet Laser Cutting Machine

Metal Sheet Laser Cutting Machine

(1)A metal sheet laser cutting machine is a high-tech piece of equipment designed to cut various types of metals with great precision and accuracy. It uses a laser beam to melt and vaporize the material, producing a clean and precise cut. This machine has revolutionized the metalworking industry by increasing efficiency, reducing waste, and improving the quality of cuts.

The metal sheet laser cutting machine is a highly advanced piece of equipment that uses a laser beam to cut through metal sheets. The machine consists of several components, including a laser generator, beam delivery system, cutting head, and control system. The laser generator produces a powerful beam of light that is directed through the beam delivery system and focused by the cutting head onto the metal sheet. The control system coordinates the movements of the cutting head to ensure precise and accurate cuts.

The metal sheet laser cutting machine can cut various types of metals, including steel, stainless steel, aluminum, copper, brass, and titanium. Each metal has its unique properties, and the machine can be adjusted to cut each material optimally. The thickness of the metal sheet that can be cut depends on the power of the laser and the characteristics of the metal. The machine can cut metal sheets ranging from 0.5mm to 25mm in thickness.

The metal sheet laser cutting machine has several advantages over traditional cutting methods. Firstly, it is highly precise, producing cuts with an accuracy of 0.1mm. This precision means that parts can be cut to exact specifications, reducing the need for manual adjustment and minimizing waste. Secondly, the machine is highly efficient, cutting through metal sheets quickly and with minimal operator intervention. Thirdly, the machine produces clean and burr-free cuts, reducing the need for additional processing steps. Finally, the machine can cut complex shapes and designs that would be difficult or impossible to achieve with traditional cutting methods.

The metal sheet laser cutting machine has a wide range of applications across various industries. It is commonly used in the manufacturing of automotive parts, aerospace components, medical devices, electronics, and architectural features. It can also be used in the production of signage, decorative art, and metal jewelry. The machine's versatility means that it can be used for both prototyping and mass production.

The metal sheet laser cutting machine is a highly advanced piece of equipment that has revolutionized the metalworking industry. Its precision, efficiency, and versatility make it an invaluable tool for cutting various types of metals with minimal waste and high accuracy. The machine's wide range of applications means that it has become an essential tool in various industries, from automotive manufacturing to metal jewelry production.

Jingwen is a professional laser cutting machine supplier. Browse our website to find professional equipment suitable for your business, we will provide you with professional advice and considerate service.

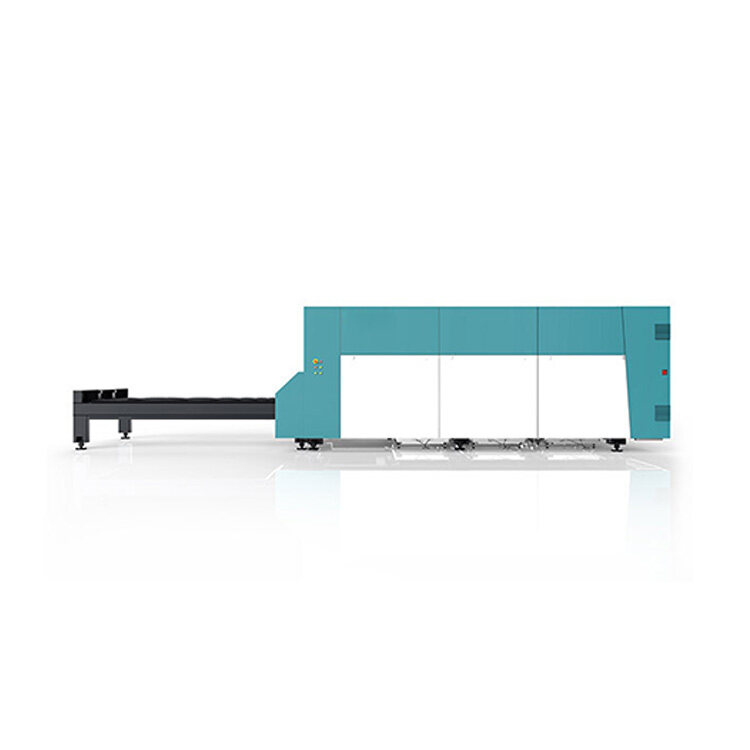

DF-3015X Metal Sheet Laser Cutting Machine

Our DF-3015X Metal Sheet Laser Cutting Machine uses an imported servo motor that offers excellent performance, high speed, stability, and durability, ensuring the machine's overall high speed and acceleration.