Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

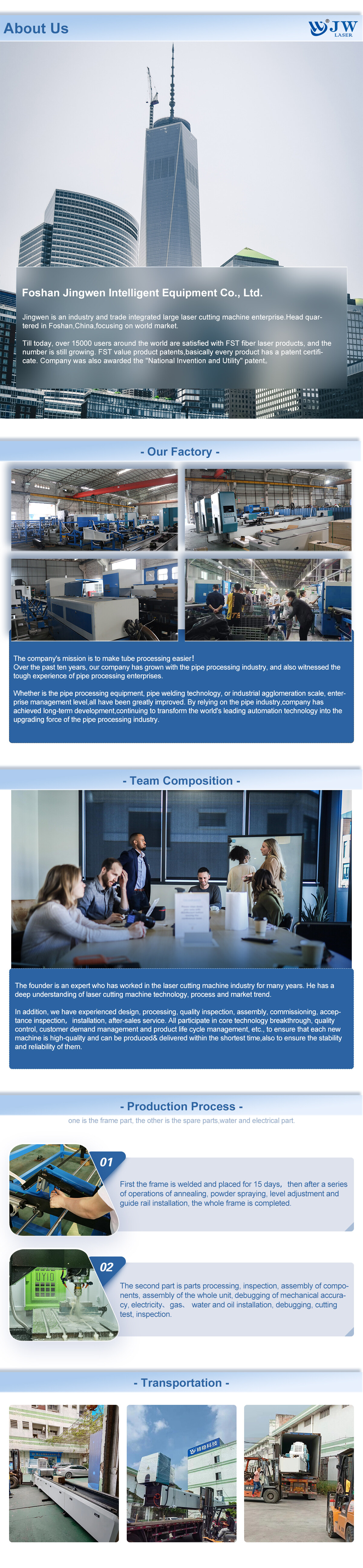

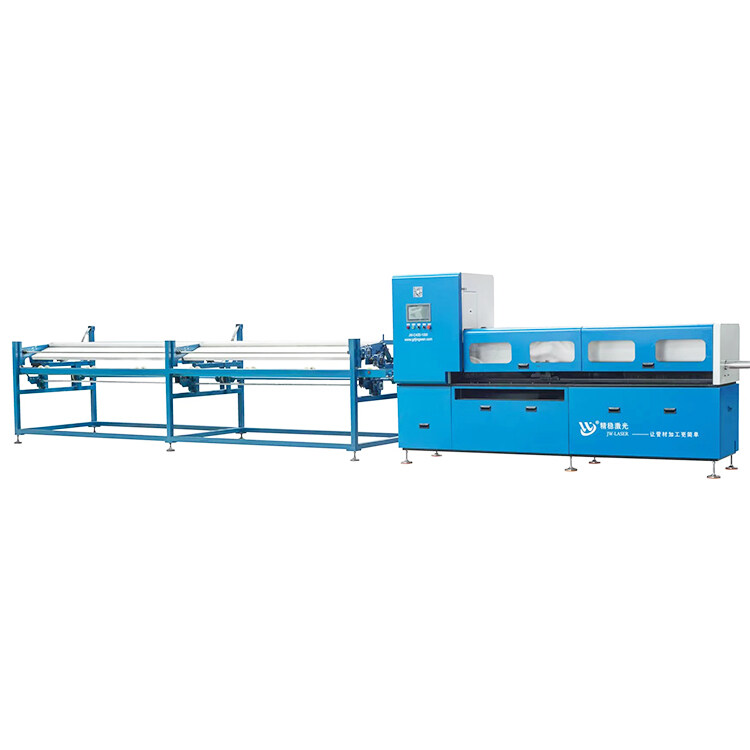

C150D aluminum round pipe laser cutting machine

A high-end tool for precisely cutting pipe materials is the round pipe laser pipe cutter. A laser, a gantry, a machine tool, a round pipe fixture, a numerical control panel, and a cooler are the typical components. In addition to cutting round pipes, the round pipe laser pipe cutting machine can also bevel cut various materials like square and flat pipes as well as cut, punch, hollow out, and engrave the pipe wall.

C150D aluminum round pipe laser cutting machine

The round pipe laser pipe cutting machine is a high-end equipment for the precision cutting of pipe materials. It is generally composed of a laser, a gantry, a machine tool, a round pipe fixture, a numerical control console, and a cooler. In addition to cutting round pipes, the round pipe laser pipe cutting machine can also cut, punch, hollow out, and engrave the pipe wall, and bevel cutting for other materials such as square pipes and flat pipes.

The advantages of the C150D aluminum round pipe laser cutting machine

- The cutting precision is high, and the contour precision can reach ±10 wires.

- The incision is flat, without burrs, the kerf is thin, and the material loss is small.

- Non-contact processing and the heat-affected zone of laser cutting are very small, and there is almost no deformation.

- The cutting efficiency is high, and mass production can be realized.

- Good flexibility, using professional numerical control systems and kitting programming software, products can be changed or replaced at any time.

The Safety Regulations of C150D aluminum round pipe laser cutting machine

Laser-cutting machines must operate under safe and reliable conditions, and the safety regulations are as follows:

- laser has adverse effects on the human body. During the operation, it is necessary to protect the weak parts of the body, such as the eyes, exposed skin, etc. It is not suitable to look directly at the laser during cutting with the eyes.

- During the operation, any part of the human body cannot be within the running track of the beam to avoid being bruised.

- During the operation, the laser, the fuselage, and the circuit control cabinet of the chiller cannot be opened to prevent the harm of high-voltage electricity to the human body.

- The laser cutting machine must be powered off before maintenance, and the power can be checked after the maintenance is completed.

- There should not be any flammable materials or fire sources near the gas cylinder sticking point.