Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

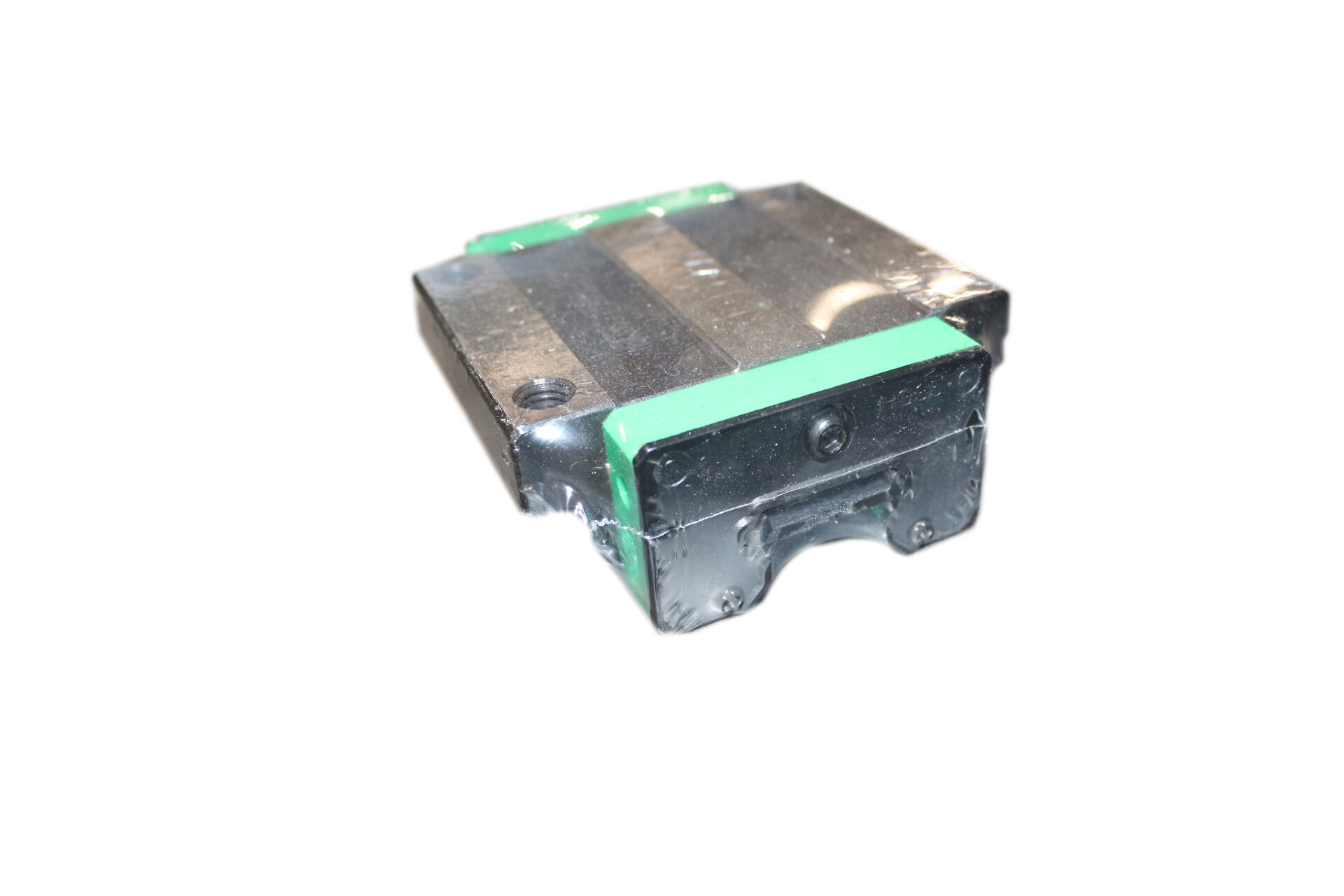

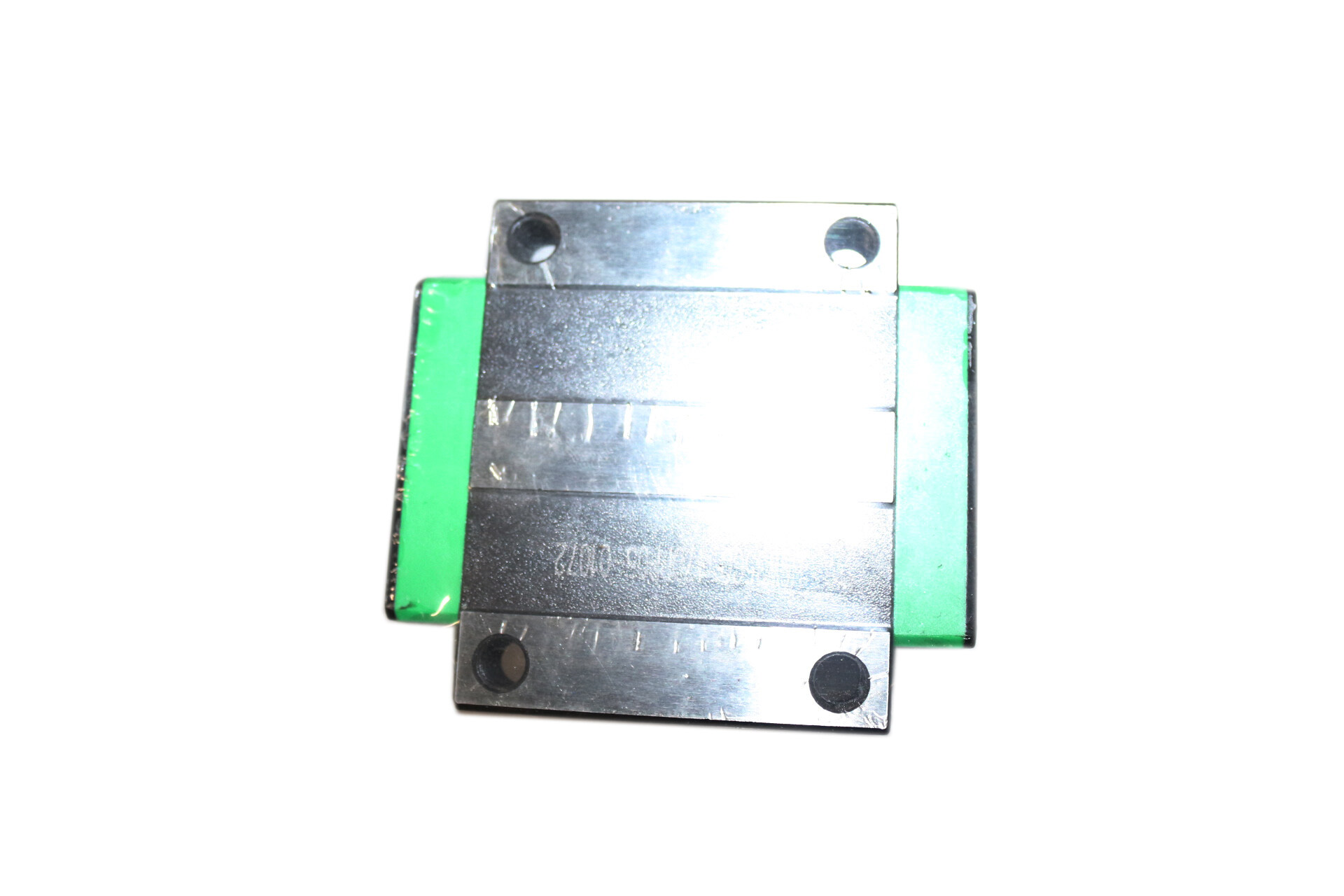

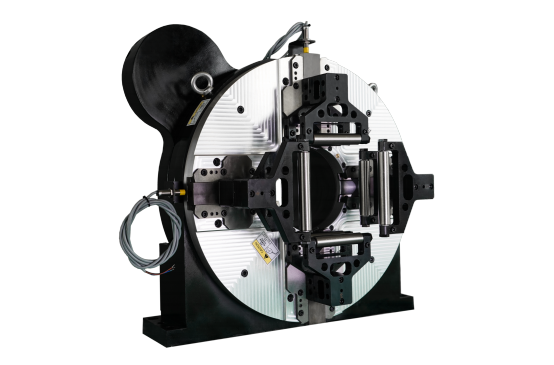

Precision Rail

A type of workpiece called a precision rail causes the slider to move back and forth on the guide rail by use of balls or rollers. It has a high positioning accuracy and high stiffness and has a friction coefficient of 1/40 of the conventional hard rail. It is therefore frequently used in CNC machine tools, automation, CNC woodworking machinery, optical fiber cutting machines, drilling machines, 3C electronics, glass edge grinders, advertising printing machines, picture machines, and other industrial equipment.

Precision Rail

The precision rail is a kind of workpiece that uses balls or rollers to make the slider reciprocate on the guide rail. It is 1/40 of the friction coefficient of the traditional hard rail and has high positioning accuracy and high rigidity. Therefore, it is widely used in CNC machine tools, automation, CNC woodworking machinery, optical fiber cutting machines, drilling machines, 3C electronics, glass edge grinding machines, advertising printing, photo machines, and other industrial equipment.

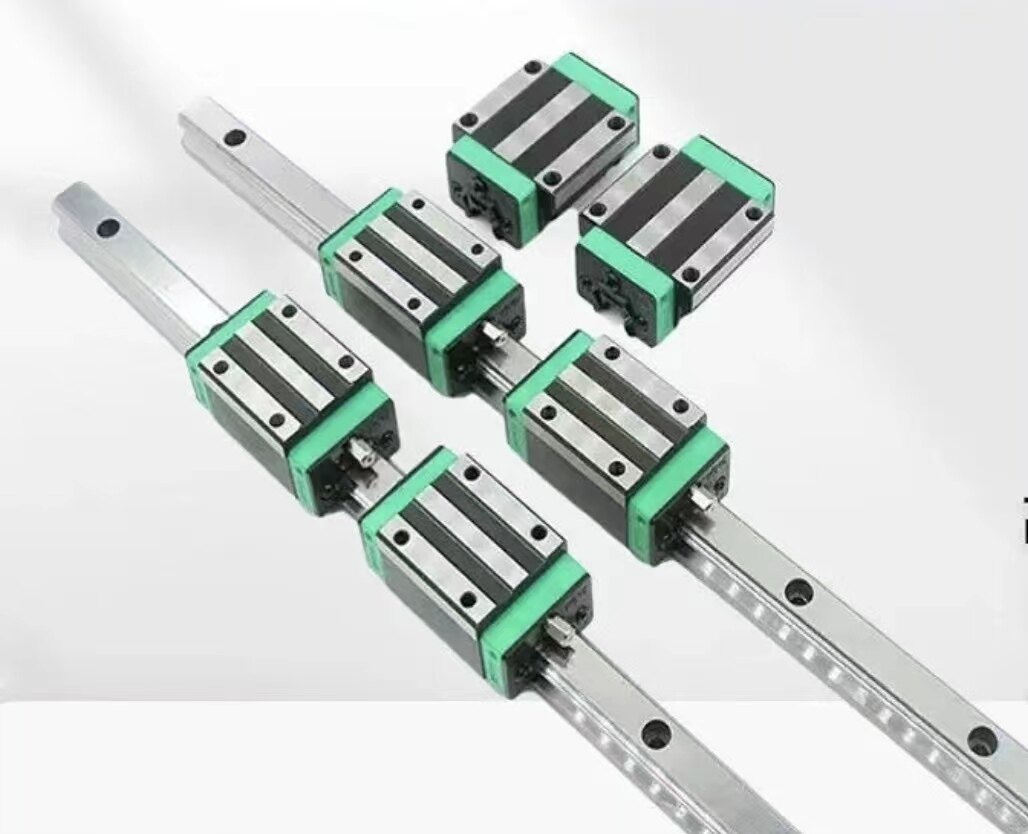

The application field of Precision Rail

- Precision guide rails are mainly used in automatic machineries, such as imported machine tools, bending machines, laser welding machines, etc. Of course, linear guide rails and linear axes are used together.

- Precision guide rails are mainly used in mechanical structures with relatively high precision requirements. There is no intermediate medium between the moving elements and fixed elements of the precision guide rails, but rolling steel balls are used. Because the rolling steel ball is suitable for high-speed motion, with a small friction coefficient and high sensitivity, it meets the working requirements of moving parts, such as tool holders and carriages of machine tools. If the force acting on the steel ball is too large, the steel ball will be preloaded for too long, resulting in increased movement resistance of the bracket.

The precautions of Precision Rail

- Prevent rust

When directly taking the linear guide rail by hand, the sweat on the hands should be fully washed off and coated with high-quality mineral oil before operation. In the rainy season and summer, special attention should be paid to anti-rust.

- Keep the environment clean

Keep the linear guideway and its surrounding environment clean Even if tiny dust that is invisible to the naked eye enters the guideway, it will increase the wear, vibration, and noise of the guideway.

- Install carefully

When using and installing the linear guide rail, it is necessary to be careful and careful. Strong stamping is not allowed. It is not allowed to directly hit the guide rail with a hammer. It is not allowed to transmit pressure through the rolling elements.

- The installation tool should be suitable

Use suitable and accurate installation tools for linear guide rails, use special tools as much as possible, and try to avoid using things like cloth and short fibers.